Forming parts by casting Review questions

1. What are some of the factors which govern the selection of the best method for casting a machine part?

2. Briefly describe the process of sand casting.

3. What are some of the common metals used in the sand-casting process?

4. Why must the patternmaker provide shrinkage allowance on a pattern?

5. Describe a shrink rule and tell how it is used.

6. What special symbol on a drawing tells the patternmaker where to add stock for machining allowance!

7. Describe the use of a flask in sand casting. What are the two main parts?

8. Explain the use of a parting line on ; pattern. Is the position of the parting line shown on the drawing? Explain.

9. What is the purpose of draft! Is the amount of draft specified on a drawing

10. Who is responsible for determining the construction details of the pattern?

11. What is the purpose of a core!

12. Describe how a core is held in its proper position in a sand mold.

13. In a sand casting, the metal is poured into the impression left by the pattern through a hole in the sand. What is this hole called?

14. In a sand casting, gases escape through the porous sand and through holes made for this purpose. What are these holes called?

15. After pouring the metal, how is the sand core removed?

16. Briefly describe the process of die casting.

17. Explain why die casting is considered economical only in the production of a large quantity of parts.

18. What is done to the mold in die casting so that several parts may be molded at the same time?

19. What are the major advantages of the die-casting process?

20. Explain the reason why iron and steel parts cannot be made by the die-casting process.

21. List some of the metals which are more commonly used for die casting.

22. Are separate drawings prepared for the diemaker and the machinist for die-cast parts? Explain.

23. Which of the following words describes the amount of machining necessary for die-cast parts? (a) Great, (b) Moderate, (c) Little, if any.

24. Prepare a brief outline to describe the process of precision investment casting.

25. Approximately when was the precision investment casting process adapted for commercial and military use in the U.S.?

26. What are the major advantages of this process?

27. What are some of the limitations?

28. Briefly describe the process of permanent mold casting.

29. How does this process differ from sand casting? Give the advantages of permanent mold casting.

30. How would you compare the production rate of permanent mold castings to the production of sand and die castings?

31. What are some of the common metals used in the permanent mold process?

32. Why is the process generally limited to parts with reasonably simple shapes?

33. What is meant by a finished surface?

34. When a machine part is to be machined all over, should finish marks be applied to each surface? Explain.

35. Make a freehand sketch of one or more parts showing the following features:

a. fillet. b. round,

c. rib.

d. web.

e. boss. f. pad.

g. lug. h. runout.

Problems

Prepare detail drawings of the problems which are shown on the following pages. It will be necessary to study all of the information contained on the illustration and also the data which accompany each problem.

References have been provided for the important elements of each problem such as machining and manufacturing processes, drafting mathematics, heat treatment, hardness testing, tolerancing, information listed in the Appendix tables, and so on.

The references listed for each problem pertain only to material not found in section 2 through 7 and in section 14. All references should be carefully checked before starting the problem.

Space the required views carefully on the drawing sheet, allowing sufficient space around the views for dimensions and notes.

For each problem prepare a detail title consisting of the part number, part name, pieces per unit, material, and the finish specifications, heat treatment, and hardness test number as required.

Important — In most cases, only the critical dimensions of each part have been given. Sizes of some of the less important features of parts have been intentionally omitted leaving the selection of these sizes to the discretion of the student.

For drawing purposes, features of parts which appear to be located on center with corresponding edges may be assumed to be central.

It is important for the student to give those dimensions which locate all of the features of the part, thus eliminating any possibility of guesswork if the drawings were to be actually used in the shop.

Do not copy the given dimensions. In many cases, the given dimensions would not be suitable for use on a two or three-view detail drawing.

Problems in this section are all similar in that each one is formed by a casting process.

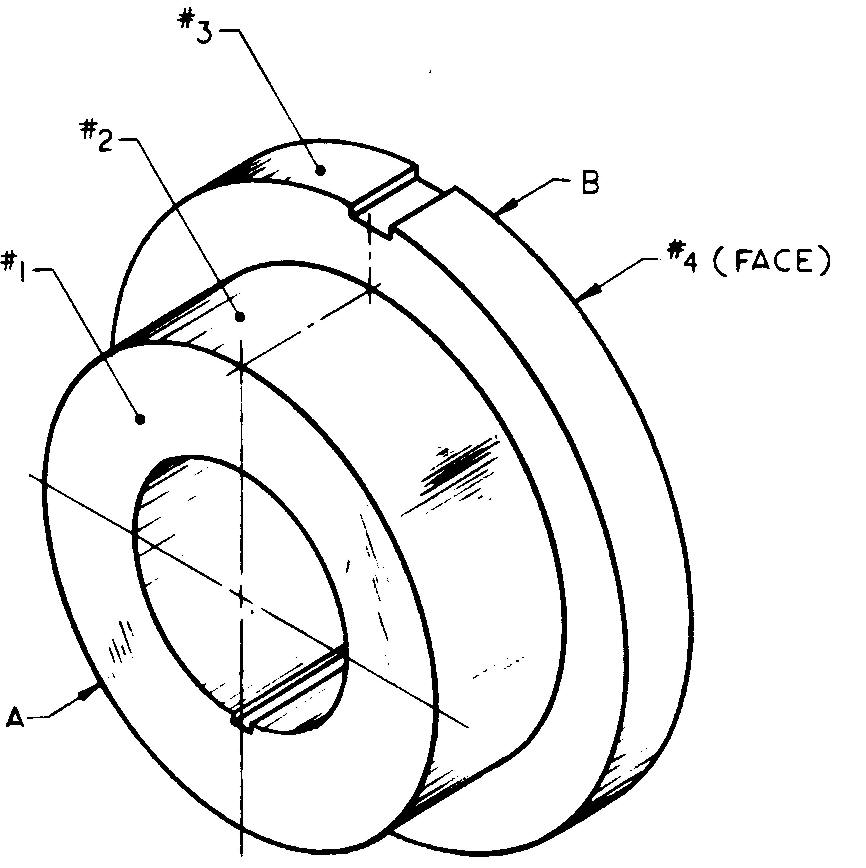

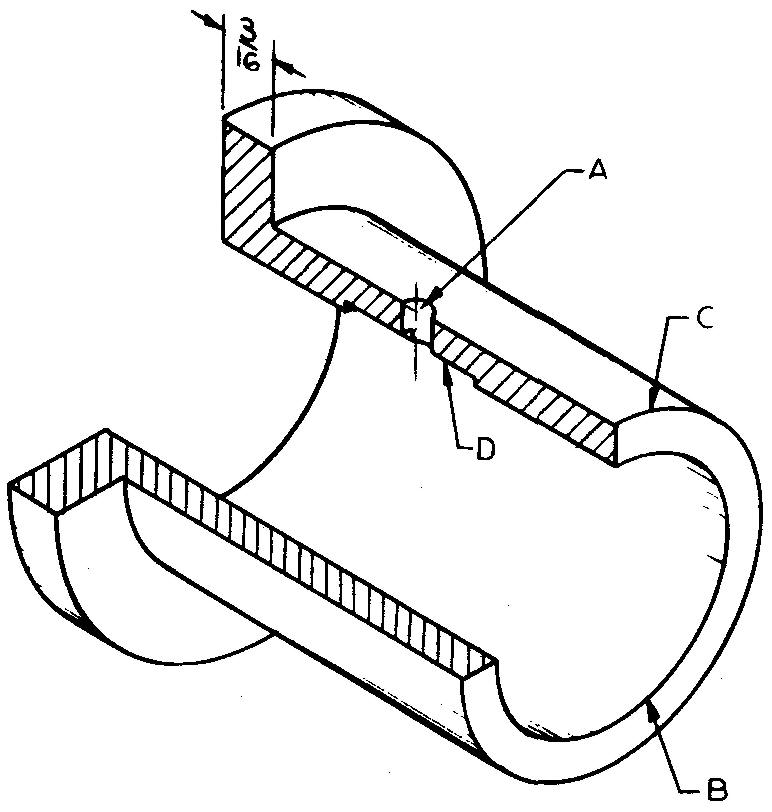

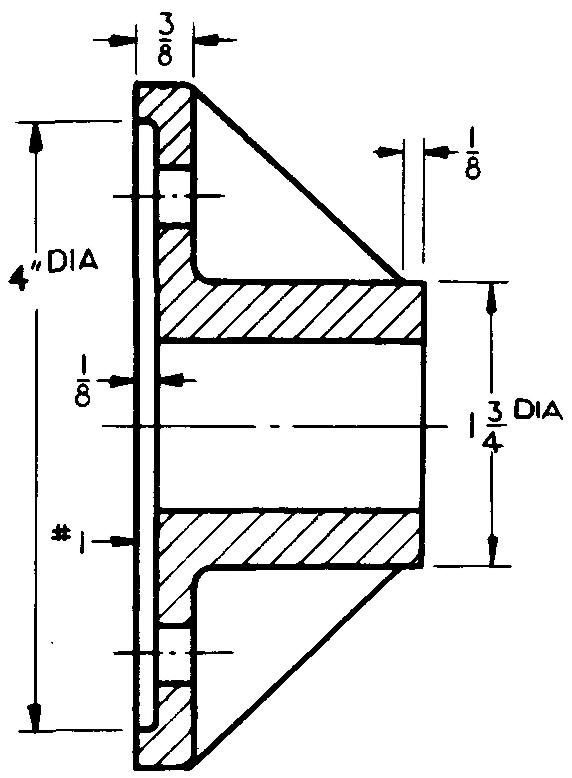

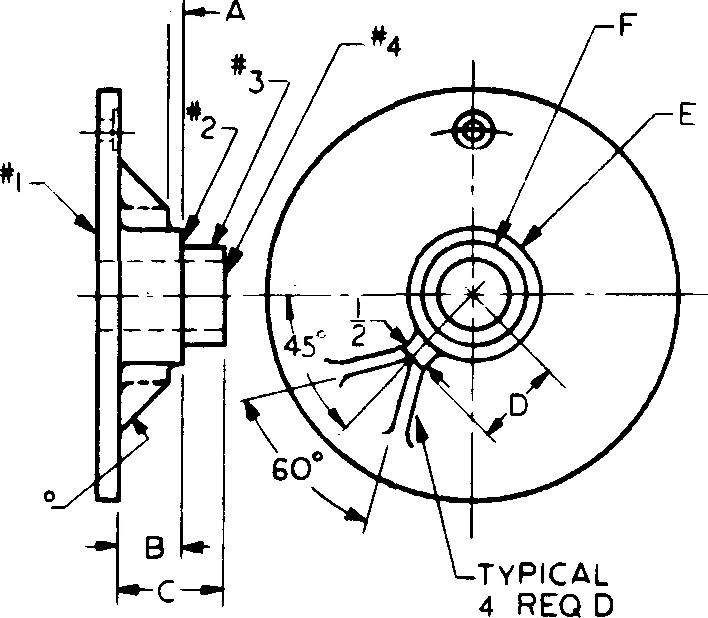

problem 14-1 spacer

Sheet Size 8-1 /2 x 11 Drawing Scale Full

Material Aluminum Alloy B356

Pieces per Unit 8 Casting Process Permanent Mold Finished Surfaces #1, #2, #3, and #4 Required Finish Symbol V

References Sees. 8 (Figs. 8-21 and 8-22), 11, 12 (Fig. 12-48), (Figs. 12-51 and 12-52), and (Fig. 12-65); Tables 6 and 48 Annodize finish.

Specify "All dias must be concentric and square with faces within +0.003 T.I.R." (Total Indicator Reading is the result obtained from an instrument known as a dial indicator gage. It is used to check the concentricity of the three diameters of the spacer.)

Slots on dia B — 3/16 wide x 1 /16 deep, 9 equally spaced

Hole — 1-5/8 dia, tolerance +.010 Keyway — To fit 1 /8 square key

Corner radii not to exceed .010 A — 3 dia x 1" lg, tolerance +.0025 B — 4 dia x 1 /2 lg, tolerance +.0025

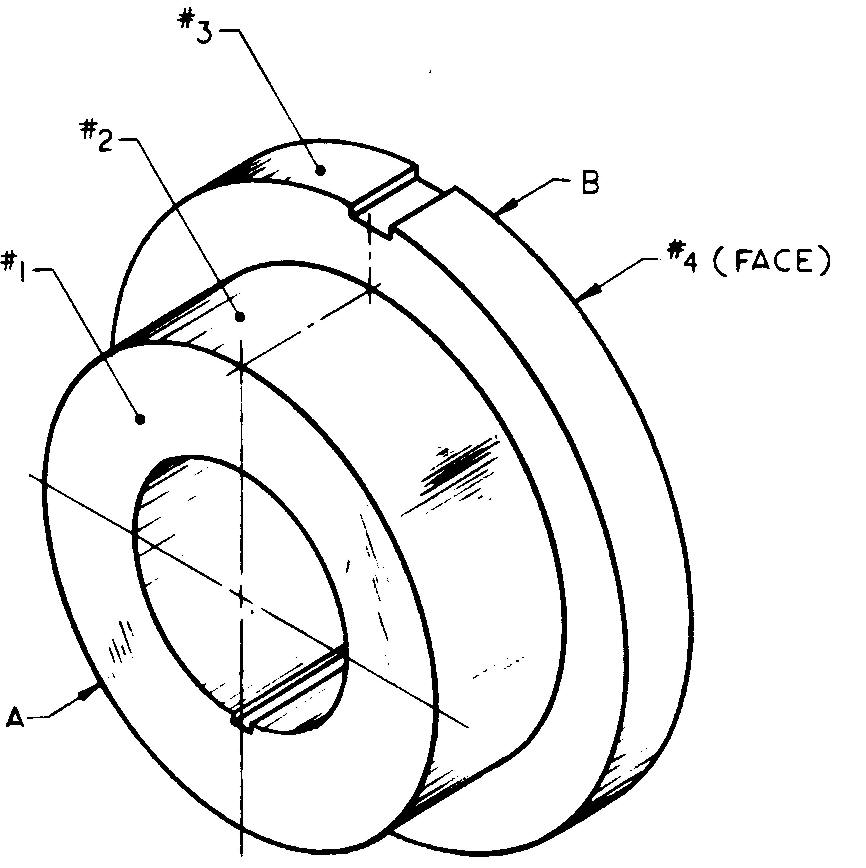

Problem 14-2 faceplate

Sheet Size 8-1 /2 x 11 Drawing Scale Full

Material Gray Cast Iron Pieces per Unit 1

Casting Process Permanent Mold

References Sees. 12 (Fig. 12-21), (Fig. 12-42), 12.22 (Figs. 12-51 and 12-52), and (Flange; Fig. 12-70); Table 8

Specify "Remove all sharp corners."

Center hole A - 1 "-8 UN ?-2 threads, 1-1/4 dia counterbore x 1/4 deep from back Flange — 4" dia x 1 /2 thick Slot — 7/16 wide Hub - 2 dia x9/16 lg

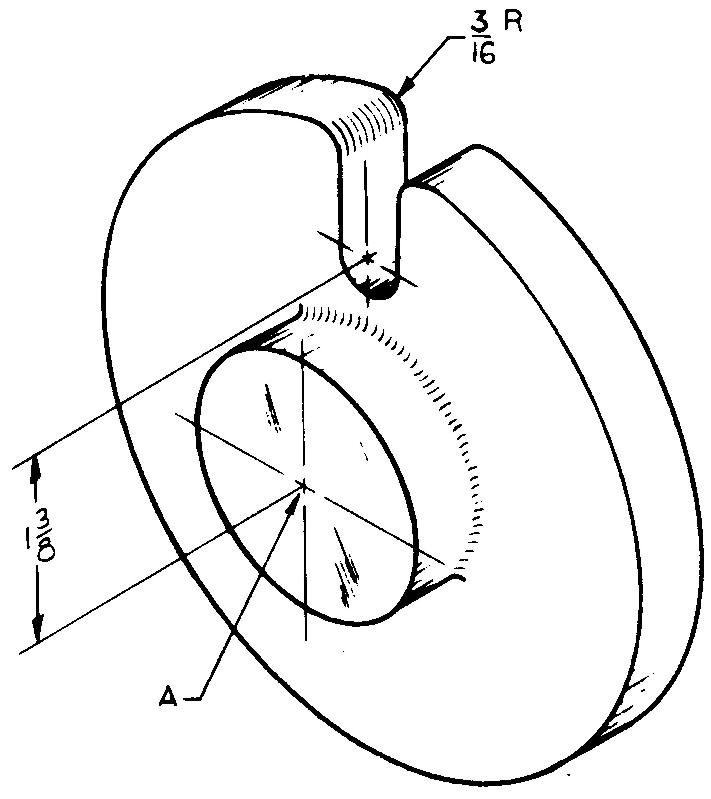

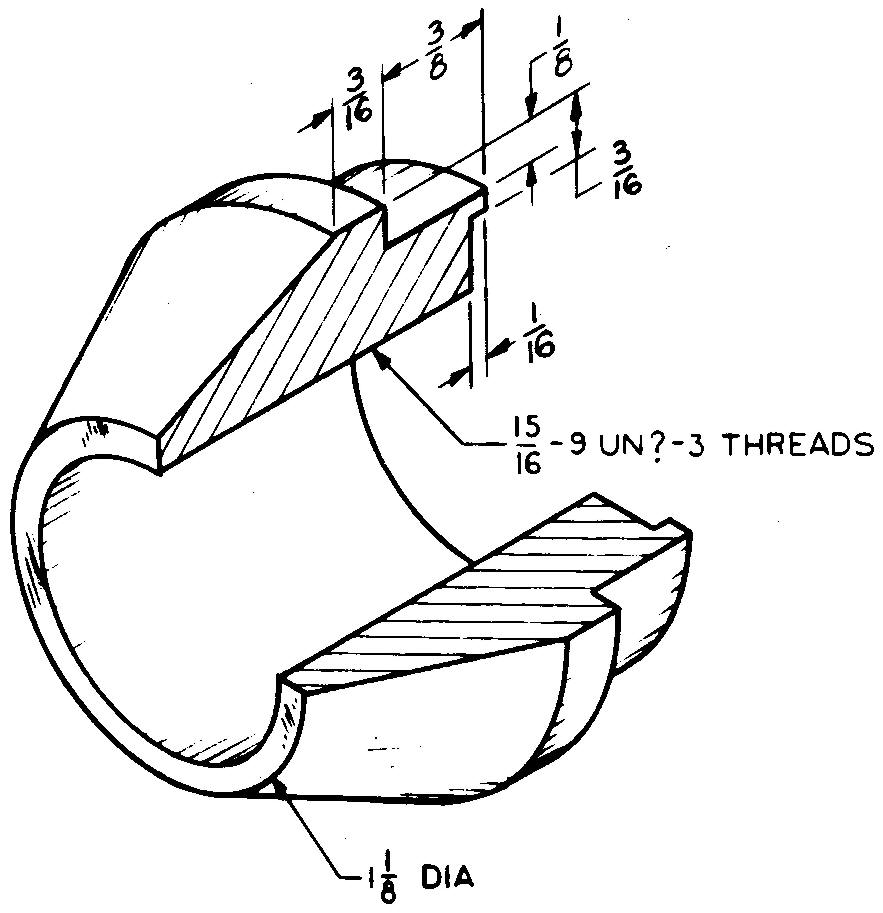

problem 14-3 threaded bushing

Sheet Size 8-1 /2 x 11 Drawing Scale Optional

Material Aluminum #346 Pieces per Unit 2

Final Part Size 1 -1 /2 dia x 2 Ig Casting Process Investment Casting

References Sees. 11, 12 (Fig. 12-40), (Fig. 12-42), and (Fig. 12-56); Table 8

Half-sectional view required. A - 1-1/4-7 UN?-3 threads x 1-1/4 deep, use detailed thread symbol B — .750 dia, tolerance +.001, -.002

problem 14-4 latch plate

Sheet Size 8-1 /2 x 11 Drawing Scale Optional

Material Aluminum #13 Pieces per Unit 2

Final Part Size 1 /2 thick x 1 -5/8 wide x 2-1 /2 lg

Casting Process Investment Casting

References Sees. 10; Table 4 Calculate and specify the total weight.

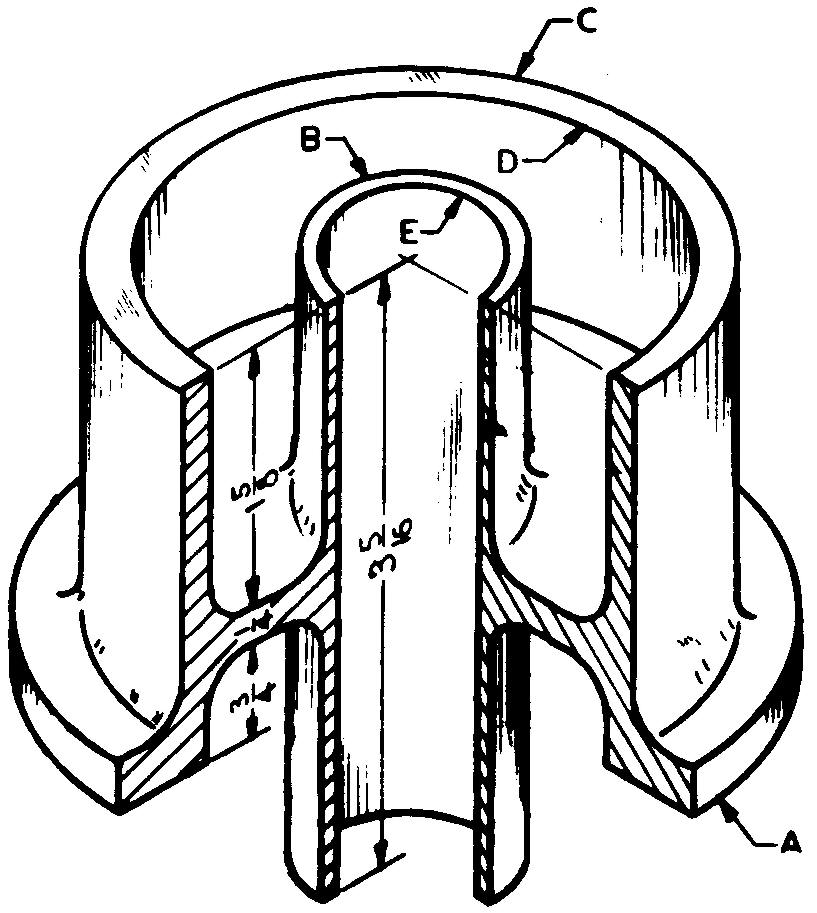

problem 14-5 end cap

Sheet Size 8-1 /2 x 11 Drawing Scale Optional

Material Copper Pieces per Unit 1 Final Part Size 3/4 lg

Casting Process Permanent Mold

References Sees. 10,11,12 (Fig. 12-35), and (Fig. 12-42); Table 4 Half-sectional view required.

Calculate and specify the total weight.

A — 1-7/8 dia

B - 2 dia x 7/32 lg

C — 1- /8 dia basic size, tolerance +.002

D — 1-9/16 dia basic size, tolerance ±.002, 1 /4 deep

E — 1/4-20 UN?-2 threads, use schematic thread symbol

All radii 1/16

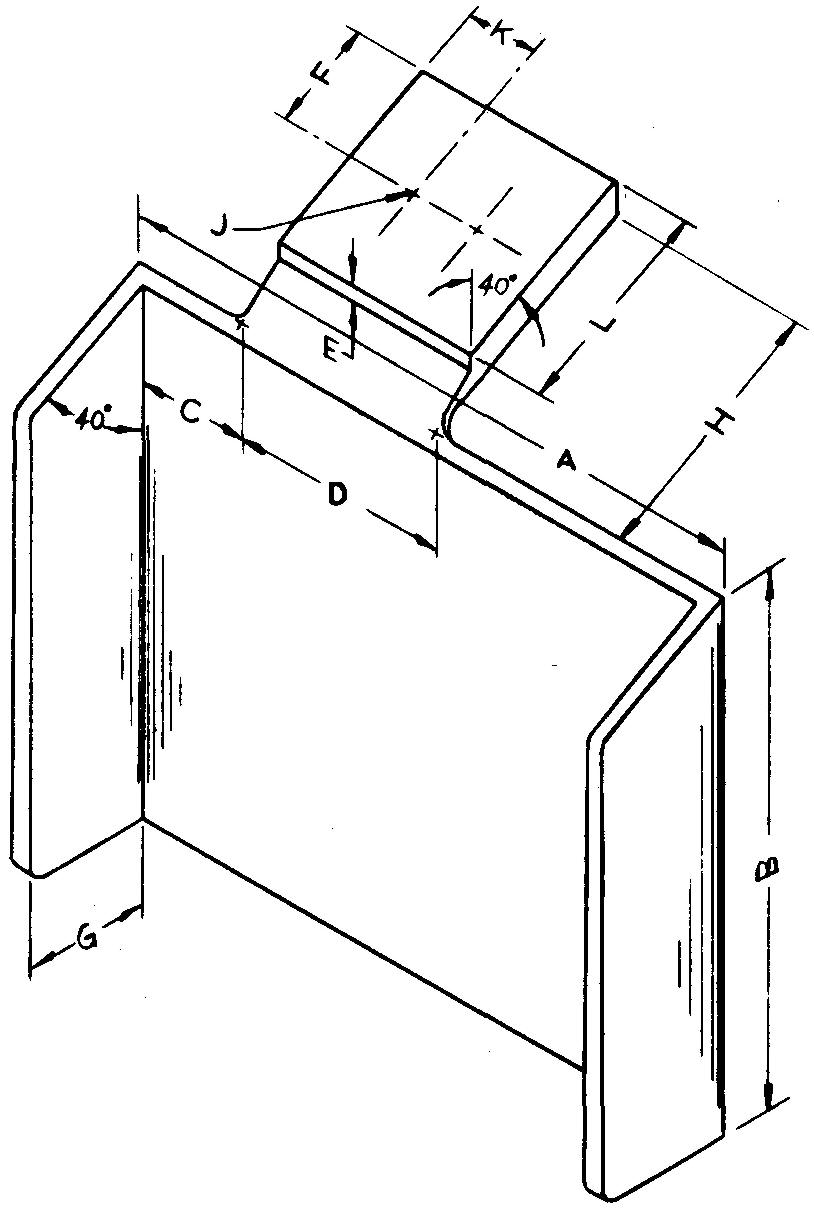

problem 14-6 end bracket

Sheet Size 8-1/2 x 11 Drawing Scale Optional

Material Gray Cast Iron Pieces per Unit 2

Casting Process Sand Casting

Finished Surfaces #1, #2, and hole J

Required Finish Symbol f

References Sees. 11, 12 (Fig. 12-6), and (Fig. 12-25); Tables 13 and 31

A - 4-5/8

B - 7-1/2

C - 3/4

D - 8

E - 5/8

F - 5-1/2

G - Clearance holes and spotface for two 7/16 dia hexagonal-head cap screws, located 5-1 /2 center to center and 1 -1 /8 from front edge

H — Clearance holes and spotface to fit four 3/8 dia tie rods with hex nuts, located on 6-1 /2 BC

J — 4-1 /2 dia bore, tolerance +.002, -.000

problem 14-7 trip lever

Sheet Size 8-1/2 x 11 Drawing Scale Twice

Material Zinc Pieces per Unit 3

Casting Process Investment Casting

References Sees. 11, 12 (Fig. 12-41), and (Fig. 12-42); Table 8

A-7/8 dia C-1/16R

B - 1 /2-20 UN ?-2 threads, 5/8 deep

problem 14-8 adjusting cap

Sheet Size 8-1/2 x 11 Drawing Scale Twice

Material Dow Metal C

Pieces per Unit 6

Final Part Size 1 -13/16 dia x 1 -3/4 lg

Casting Process Investment Casting

References Sees. 10, 12 (Fig. 12-36), and (Fig. 12-42); Table 8 Half-sectional view required. Use simplified thread symbol.

Calculate and specify the taper angle.

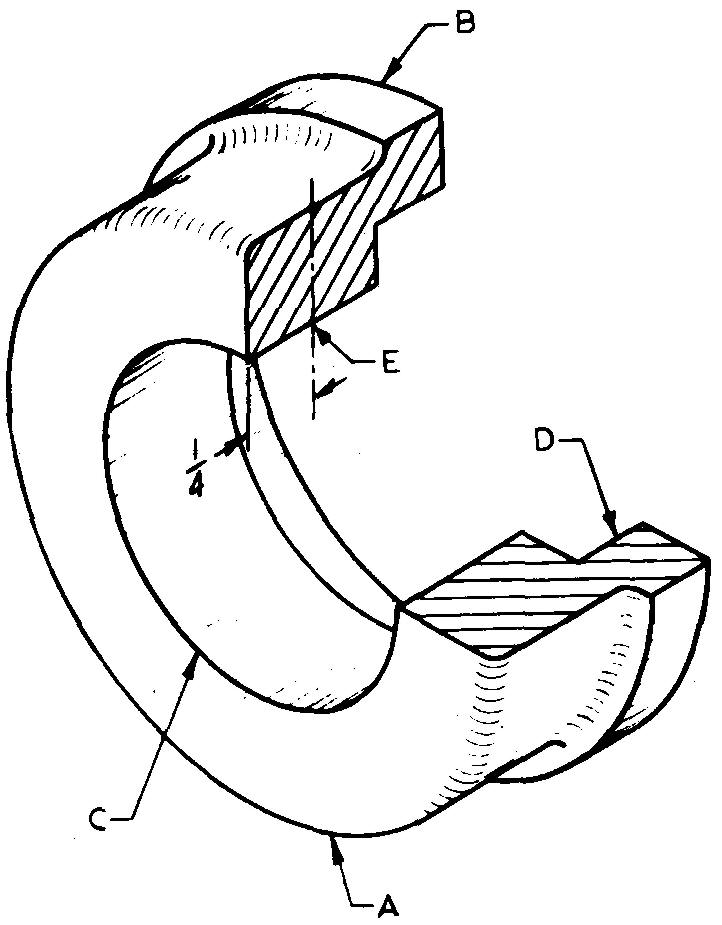

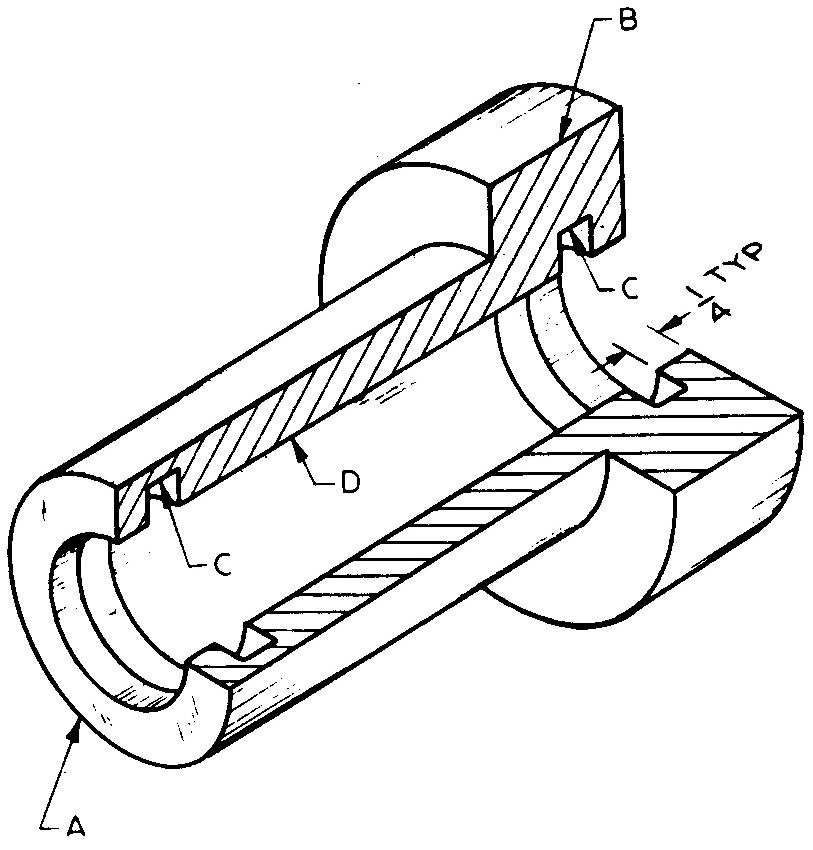

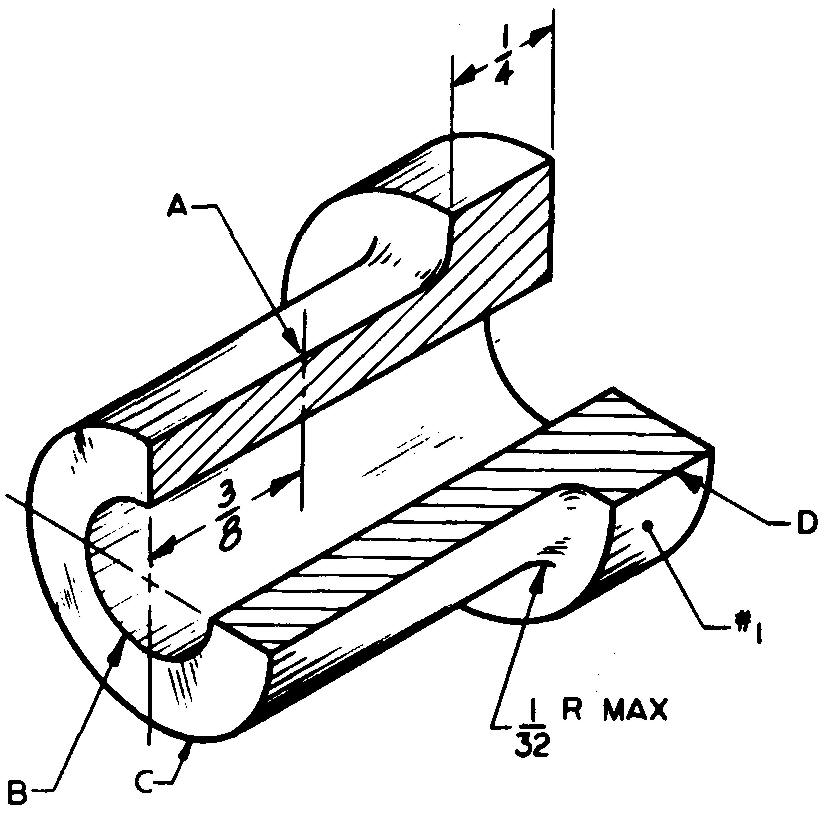

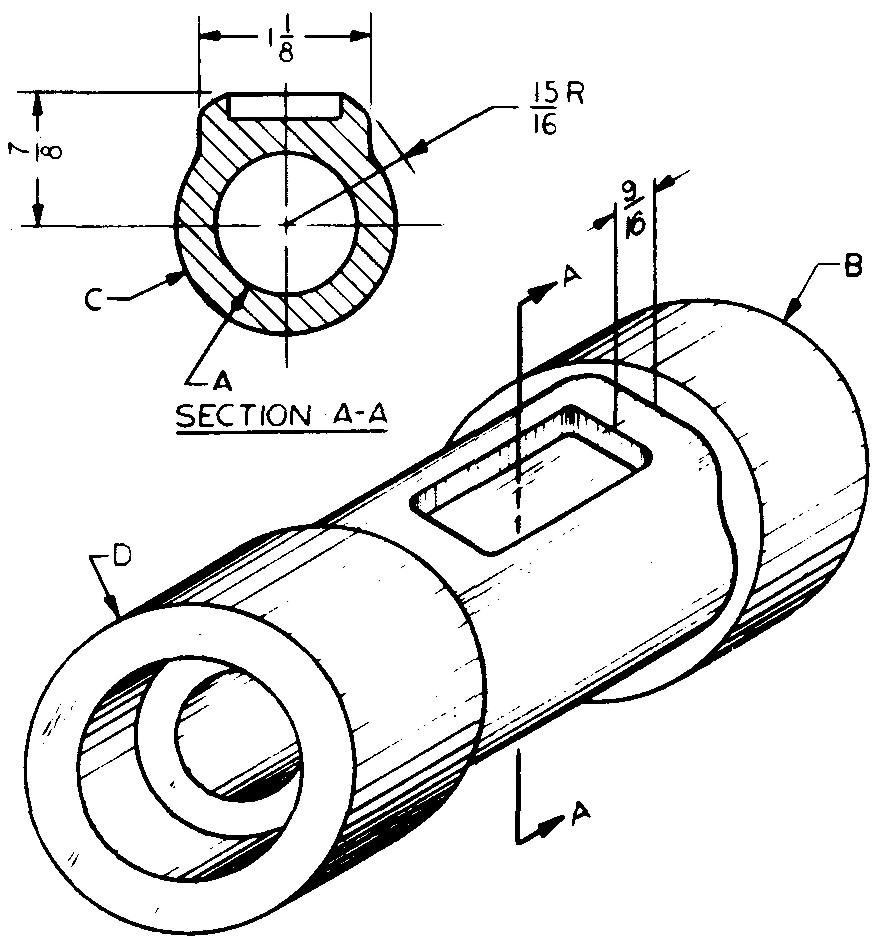

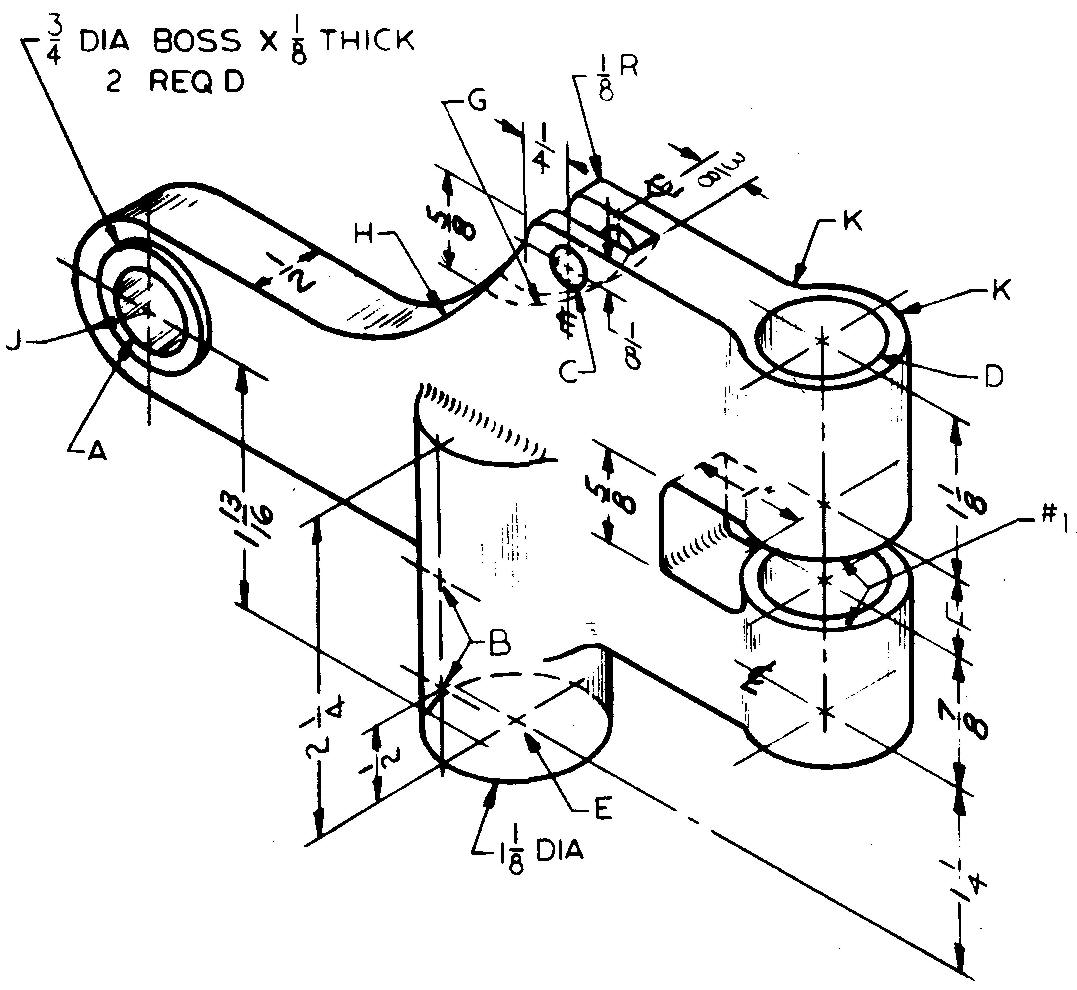

problem 14-9 bushing

Sheet Size 8-1/2x11

Drawing Scale Full

Pieces per Unit 2

Material Copper Alloy #68

Final Part Size 4 lg

Casting Process Permanent Mold

Finish Surfaces Grooves only Required

Finish Symbol V

References Sees. 8 (Figs. 8-21 and 8-22), 11, and 12 (Fig. 12-60) Half-sectional view required.

A — 1.753 dia, tolerance +.0000, -.0005

B — 2-3/4 dia x1"lg

C — 1.500 dia, tolerance +.001, 1 /4 wide

D — 1.250 dia, tolerance +.002

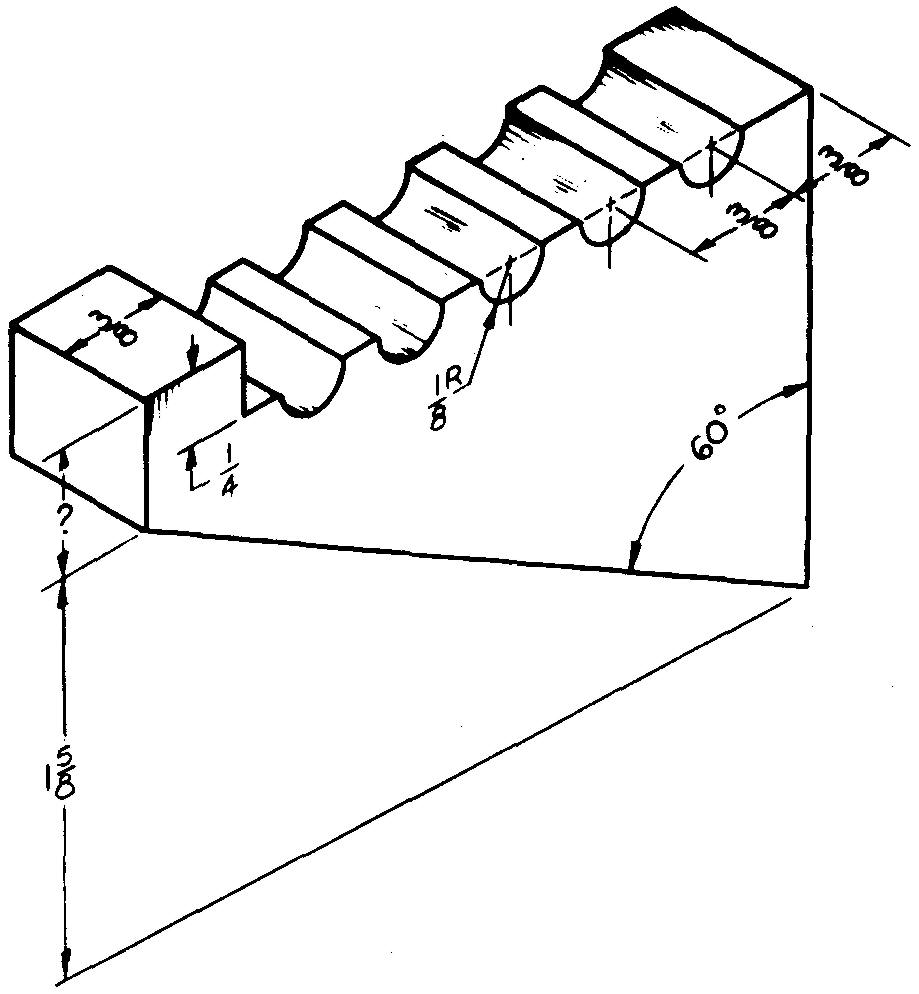

problem 14-10 sliding block

Sheet Size 8-1 /2 x 11 Drawing

Scale Twice

Material Silicon Brass

Pieces per Unit 2

Casting Process Investment Casting

References Sees. 12 (Fig. 12-4) and (Fig. 12-48)

A — 3/16 drill through, 3/8 ream, 1-1 /4 deep

B - 3/8 drill, 2 holes

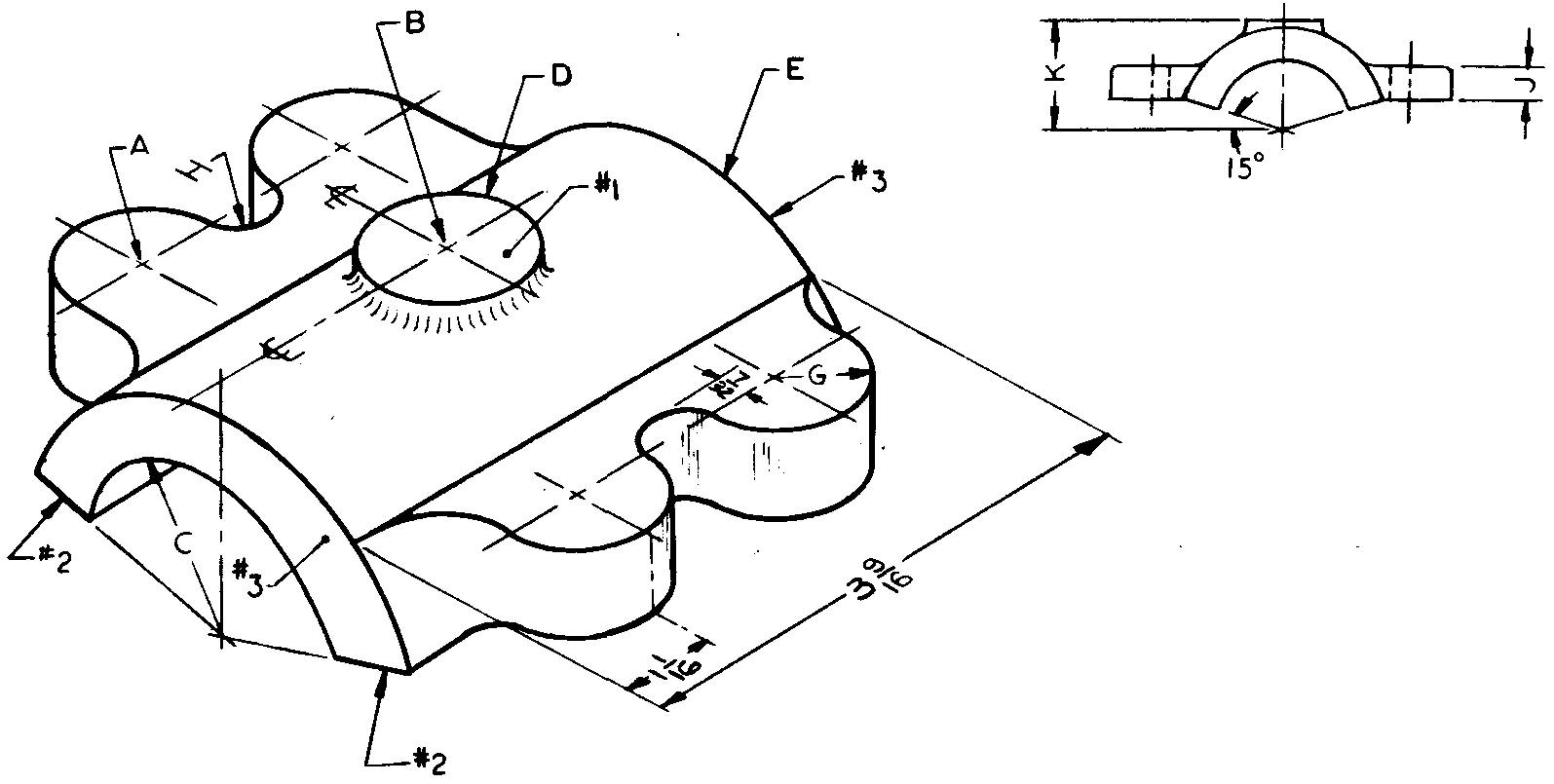

problem 14-11 locating plate

Sheet Size 8-1 /2 x 11

Drawing Scale Full

Material Aluminum #43

Pieces per Unit 1

Casting Process Investment Casting

References Sees. 10, 12 (Fig. 12-21), and (Fig. 12-48); Tables 4 and 14

Specify "All fillets and rounds 1 /8 radius."

Calculate and specify the total weight.

Disregard fillets and rounds.

A — 1 /4 ream through, 2 required

B — Drill and counterbore for 3/8 socket-head

cap screws, 2 required, locate 1-15/16 center to center

C — 5/8 ream through, boss on bottom surface centered with hole C, boss size 1 /8 x 1 -1 /4 dia

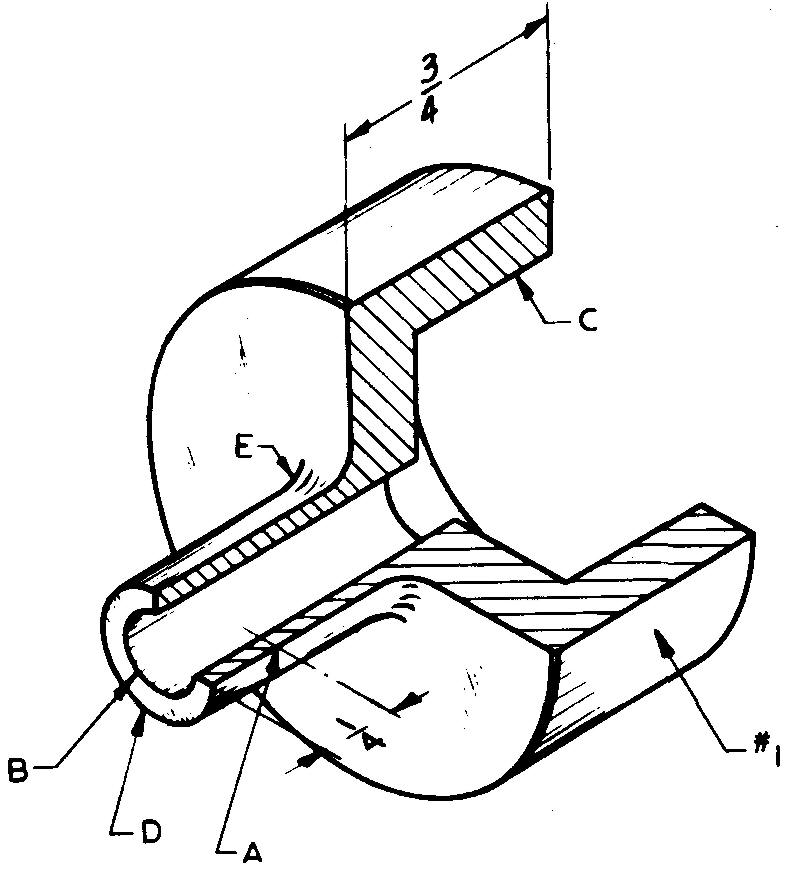

problem 14-12 coupling

Sheet Size 8-1 /2 x 11

Drawing Scale Twice

Material Aluminum Bronze

Pieces per Unit 1

Final Part Size 1-5/8 dia x 1-1 /2 lg

Casting Process Investment

Casting References Sec. 1

Half-sectional view required.

Specify "Maximum fillet and round radius + 0.015."

A — 1/8 dia hole, locate on center with ends

B — .875 dia, tolerance +.002, +.003

C — 1-1/8 dia

D — 1/16 square slot x 1/2 lg, located central with hole A

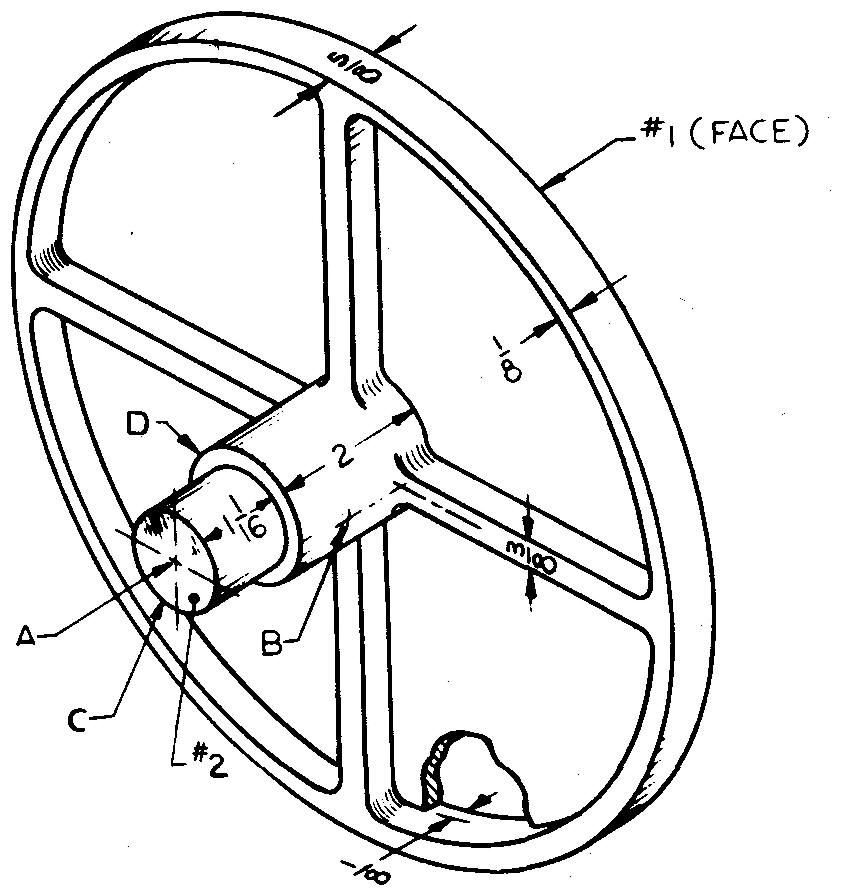

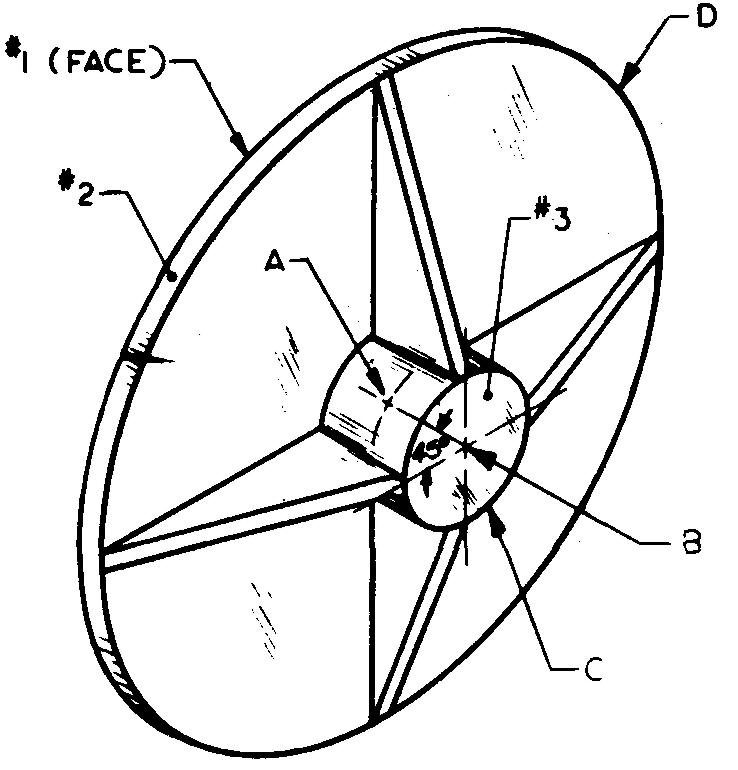

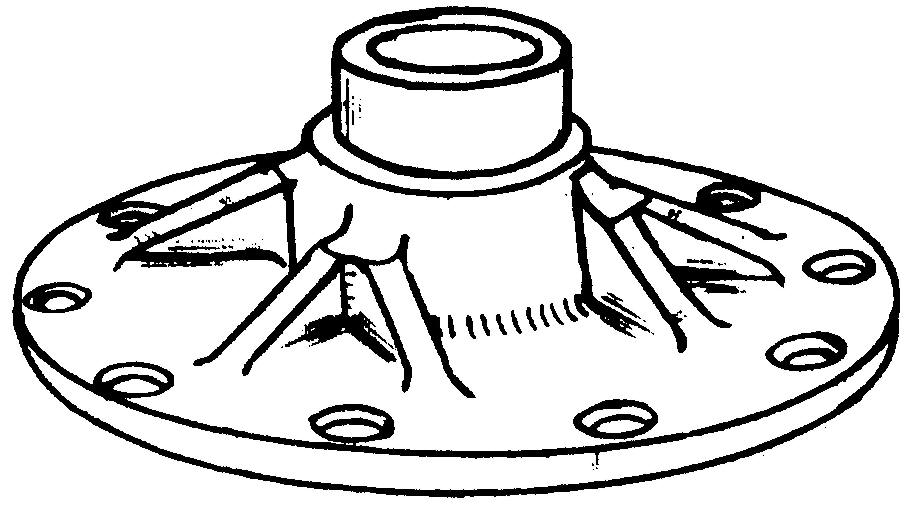

problem 14-13 sanding disc

Sheet Size 8-1/2x11

Drawing Scale Half

Material Zamak #5

Pieces per Unit 1

Final Part Size 9-7/8 OD

Casting Process Die Casting

Finished Surfaces #1, #2, and dia C

Required Finish Symbol V

References Sees. 11, 12 (Fig. 12-48), (Fig. 12-69), and (Shoulder; Fig. 12-72) (Face; Fig. 12-73); Table 38

Half-sectional view required.

Specify "Rim must be concentric with hole within +0.0025 T.I.R."

A — 5/8 ream, 2-3/8 deep

B — Hole for #4 x 2 lg taper pin, locate 3/8 from square shoulder

C — 1-11/32 dia, tolerance +.001, -.002 D - 2 dia

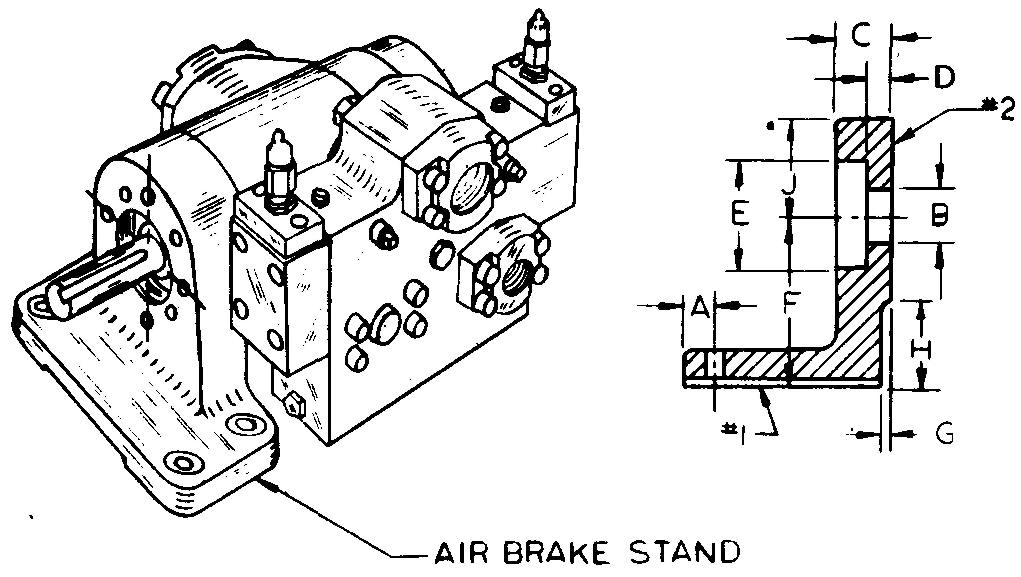

problem 14-14 air brake stand

Sheet Size 8-1/2x11

Drawing Scale Optional

Material Gray Cast Iron

Pieces per Unit 1

Casting Process Sand

Casting Finished Surfaces #1 and #2

Required Finish Symbol V

References Sees. 8 (Fig. 8-21 and 8-22), 11, and 12 (Fig. 12-25); Tables 13 and 14 Full-sectional view required.

A — 1/2

B — 1" dia hole (basic size), tolerance +.0025 +.0003

C — 1"

D — 27/64

E — 2-3/32 dia (basic size), tolerance +.005

F — 3

G - 1 /4

H — 1-1/4

J — 2R

Base holes — Drill and spotface to fit 5/16 dia

hexagonal-head cap screws, 4 required, locate 1-1/2 and 5 center to center.

Equally spaced holes (shown in pictorial view only) — To fit 1 /4 socket-head cap screws, 8 required, located on 3-1 /16 BC

Base Size — 11/16 (including pad thickness) x 2-1/2 x 6

Base pads -1/8 x 1-1/4 x 2-1 /2

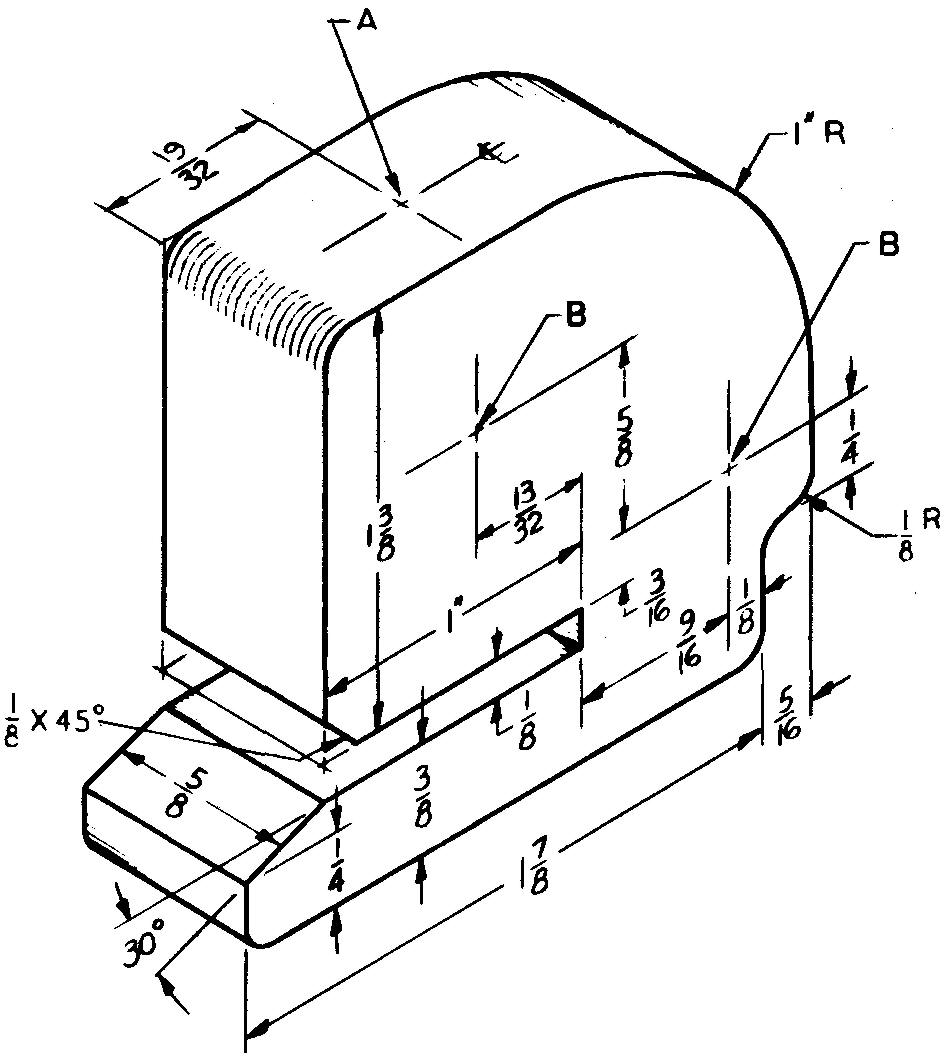

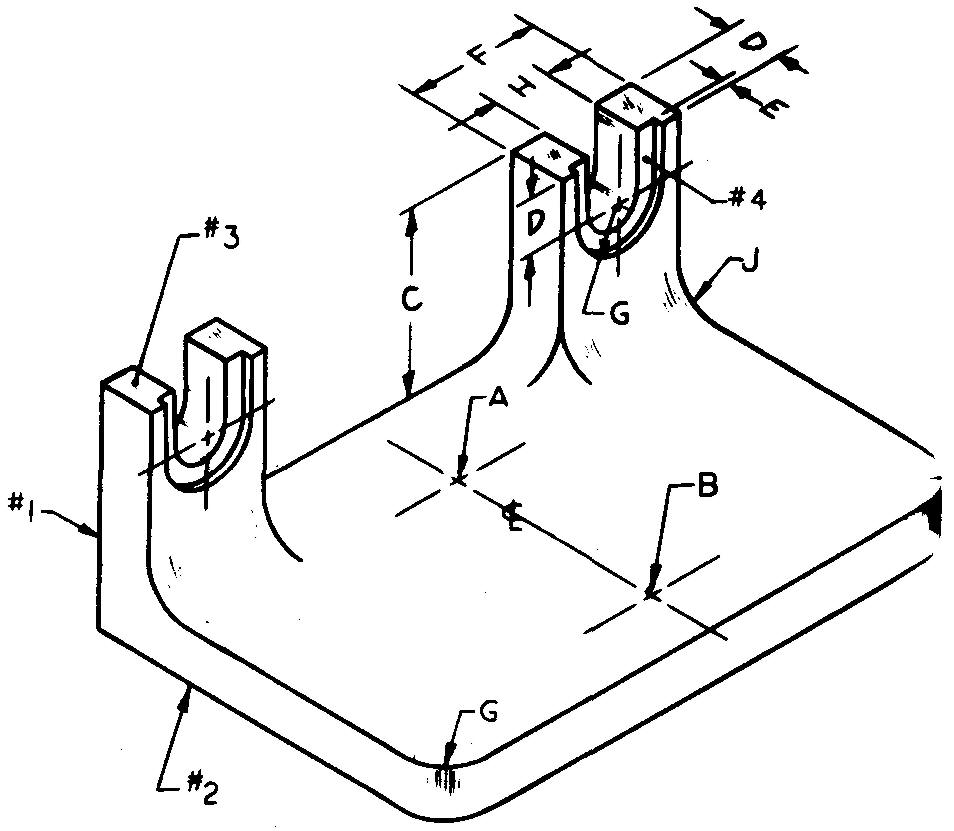

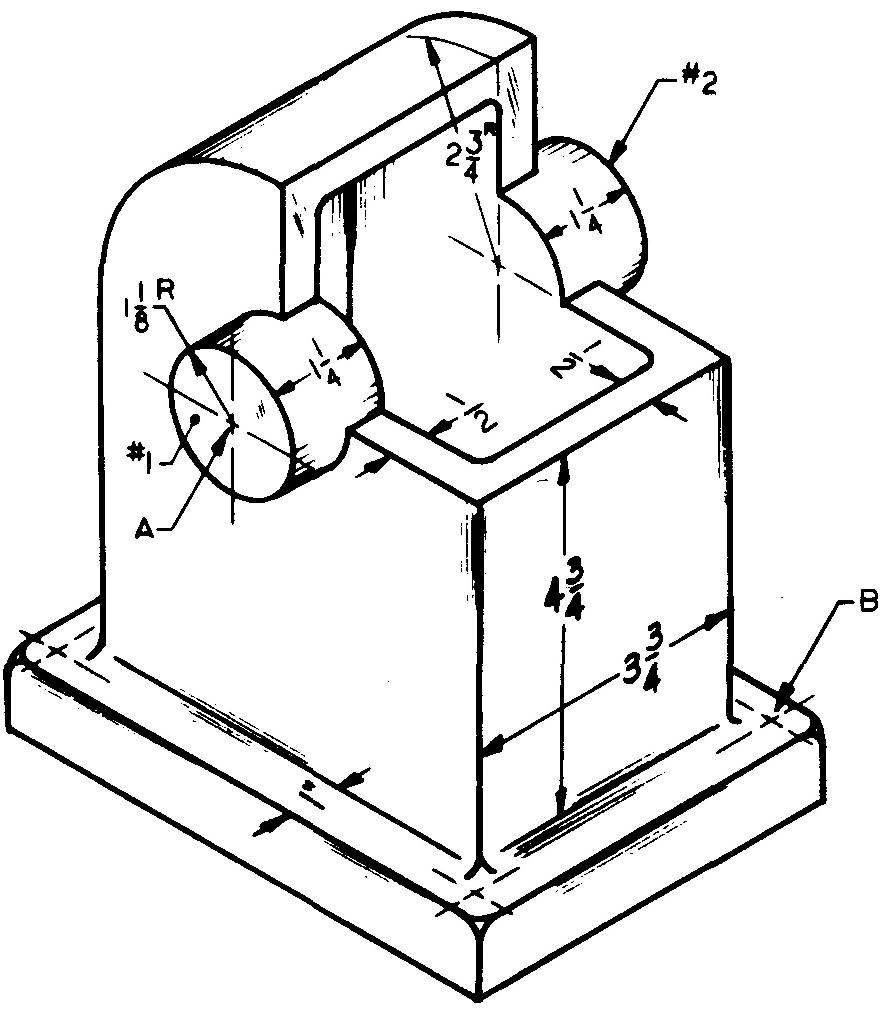

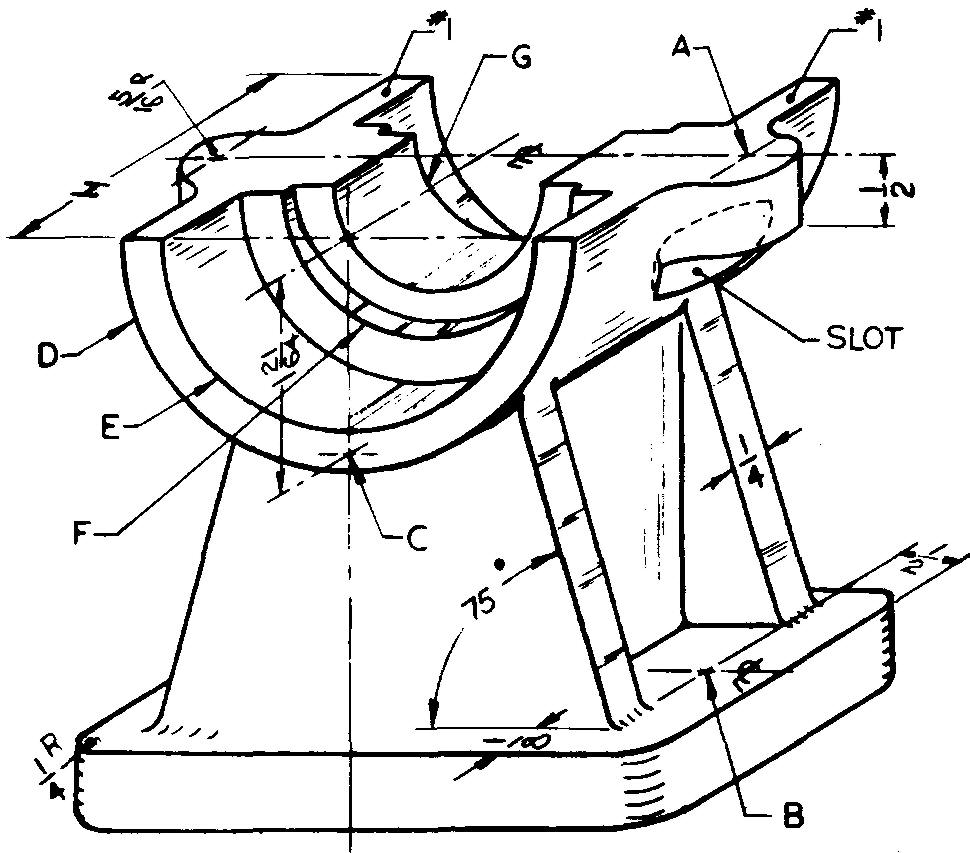

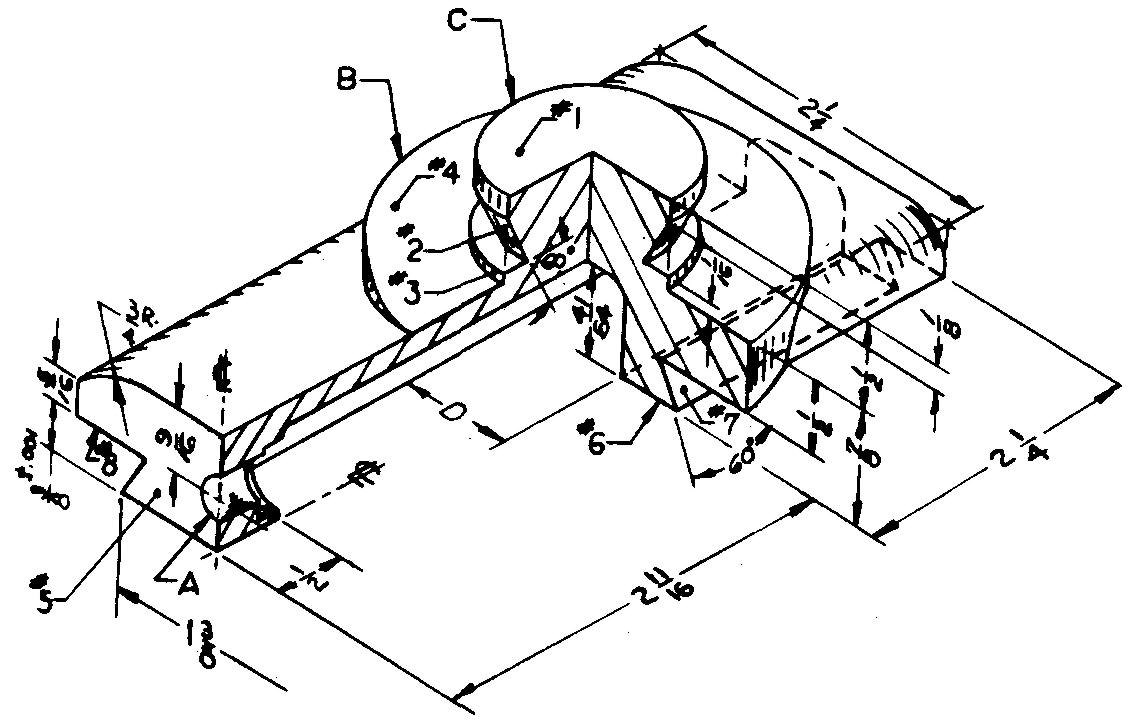

problem 14-15 yoke base

Sheet Size 11x17

Drawing Scale Optional

Material Aluminum #43

Pieces per Unit 2

Final Part Size Base — 3/8 thick x 2-11 /16 wide x 4lg

Casting Process Sand Casting

Finished Surfaces #1, #2, #3, #4, and slots H &G

Required Finish Symbol f

References Sees. 8 (Figs. 8-21 and 8-22), 12 (Fig. 12-4), (Fig. 12-48) and (Figs. 12-51 and 12-52)

Two drawings required:

1) A pattern drawing (1/8-inch machining allowance).

2) A machining drawing. Use a separate sheet for each drawing.

A — 5/8 ream through, locate 1-1/2 from B

B — 7/16 drill through, locate 7/16 from front edge

C — 1-1/4

D — 3/8

E — 1/16

F — 7/8

G — 3/8R

H — 13/32

J — 1/2R (typical)

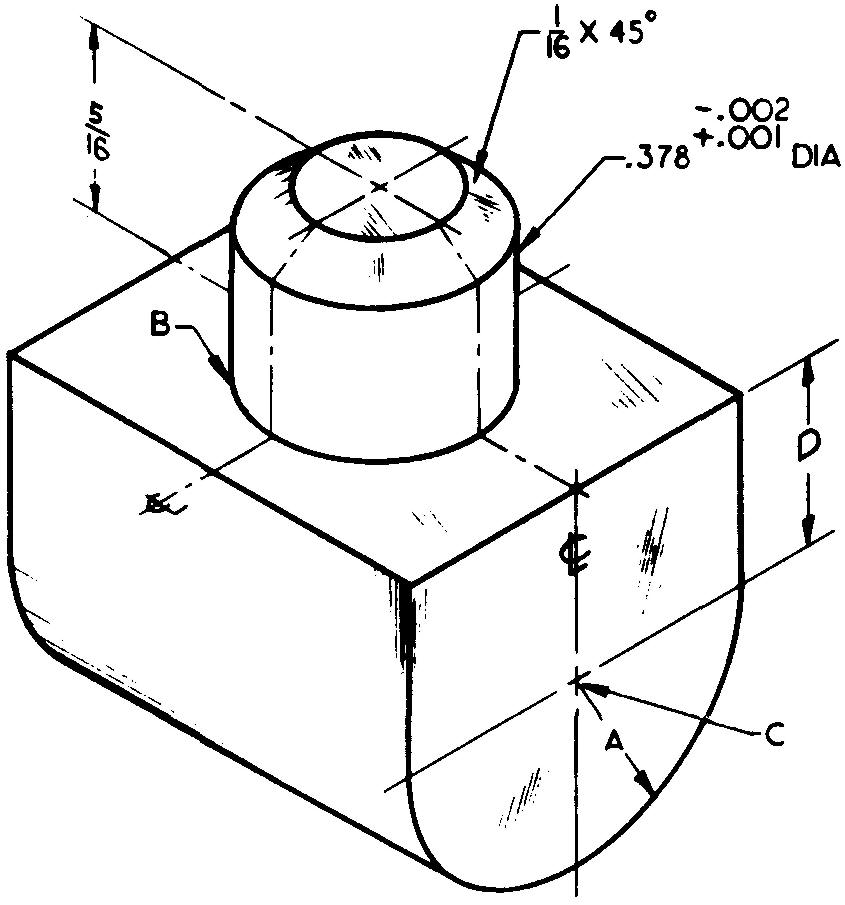

problem 14-16 positioning lug

Sheet Size 8-1/2 x 11

Drawing Scale Optional

Material Brass Pieces per Unit 4

Final Part Size 3/4 lg

Casting Process Investment Casting

References Sees. 10,11,12 (Fig. 12-42), and (Fig. 12-56); Tables 4 and 8

Specify "0.378 dia must be centered with sides and ends within ±0.005 T.I.R."

Calculate and specify the total weight.

A — 5/16 R D-21/64

B — Radius not to exceed ±.010

C — 5 /16-18 U N ?-2 threads, LH

problem 14-17 adjusting knob

Sheet Size 8-1/2 x 11

Drawing Scale Optional

Material Zamak #3

Pieces per Unit 1

Final Part Size 1-1/2 dia x 1 -11/16 lg

Casting Process Die Casting

References Sees. 8 (Fig. 8-2 and 8-9), 11, 12 (Fig. 12-48), and (Fig. 12-56)

Full-sectional view required.

A — 1/8 ream through

B — .3125 dia hole, tolerance +.005, +.004

C — 1 -1/8 dia x 1/2 deep

D —1/2dia

E — 3/32 R

Surface #1 — Cast medium knurl 1/32 x 45° chamfer at both ends

problem 14-18 thrust knob

Sheet Size 8-1/2 x 11

Drawing Scale Twice

Material Zamak #3

Pieces per Unit 1

Casting

Process Die Casting

References Sees. 8 (Figs. 8-4 and 8-9), 11, 12 (Fig. 12-36), (Fig. 12-42), and (Fig. 12-56); Table 8

Half-sectional view required.

A — #6-32 UN?-2 threads, one side only, use simplified thread symbol

B — 3/8 dia hole (basic size), tolerance ±.005

C —5/8dia x 3/4 lg

D —7/8 dia

Surface #1 — Cast fine knurl

Chamfer — 1/32 x 45° both ends of dia D

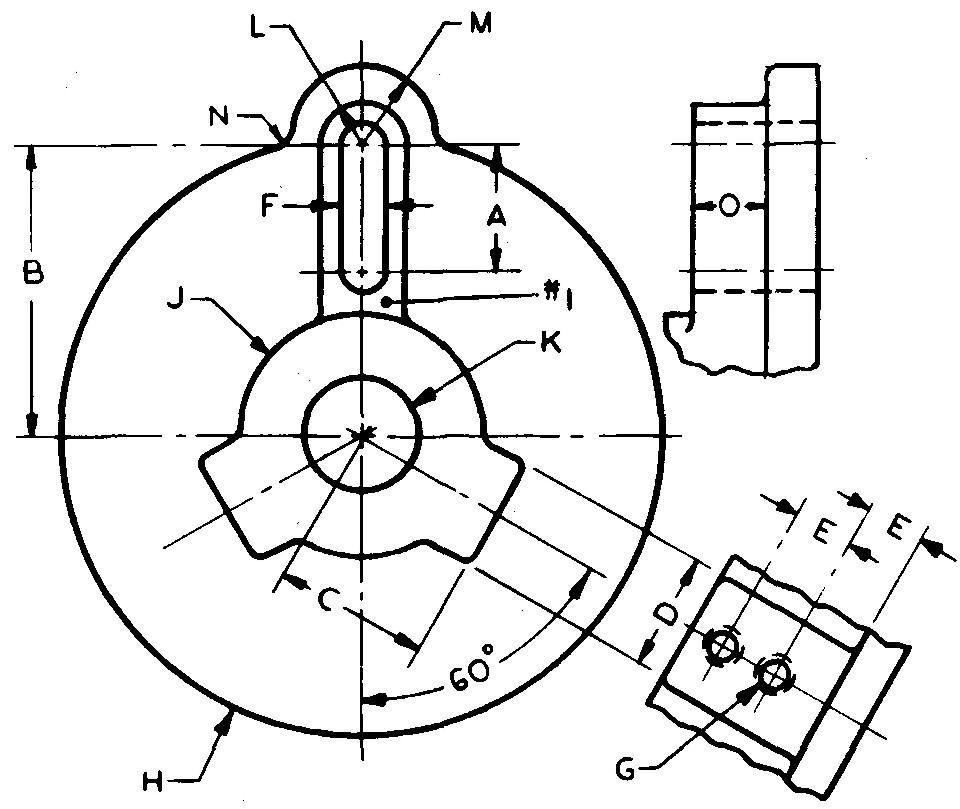

problem 14-19 crank plate

Sheet Size 11x17

Drawing Scale Full

Material Brass

Pieces per Unit 4

Casting Process Die Casting Finished

Surfaces #1 and back face

Required Finish Symbol f

References Sees. 8 (Figs. 8-21 and 8-22), 11, 12 (Fig. 12-36), (Fig. 12-42), (Figs. 12-51 and 12-52), and (Shoulder; Fig. 12-72); Table 8

Use a conventional representation for the sectional view.

A — 1-3/4

B — 4-1/4

C — 2-1/2

D — 2

E — 13/16

F — Clearance slot for 3/4 bolt

G — 1/2-13 UN ?-2 threads to hole K, 2 required in each lug, use simplified thread symbol

H — 8-1/2 dia x 5/8 thick

J — 1-7/8 R x 2-1/16 lg

K — 1-1/2 dia hole, tolerance +.002

L — 3/4R

M — 1-1/4R

N — 1/4R 0 - 1"

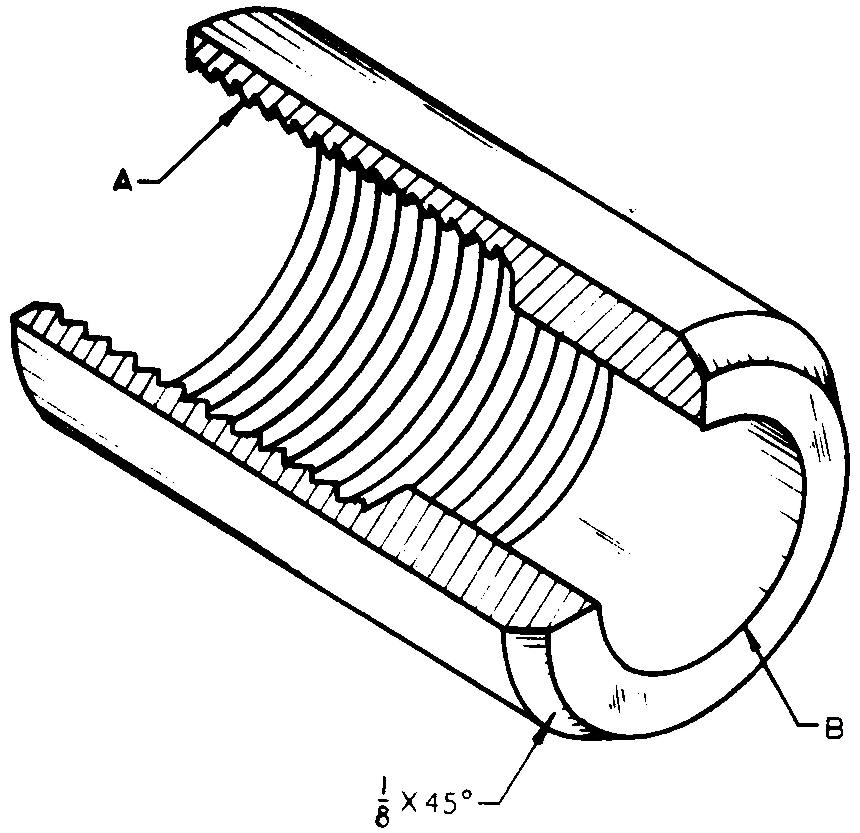

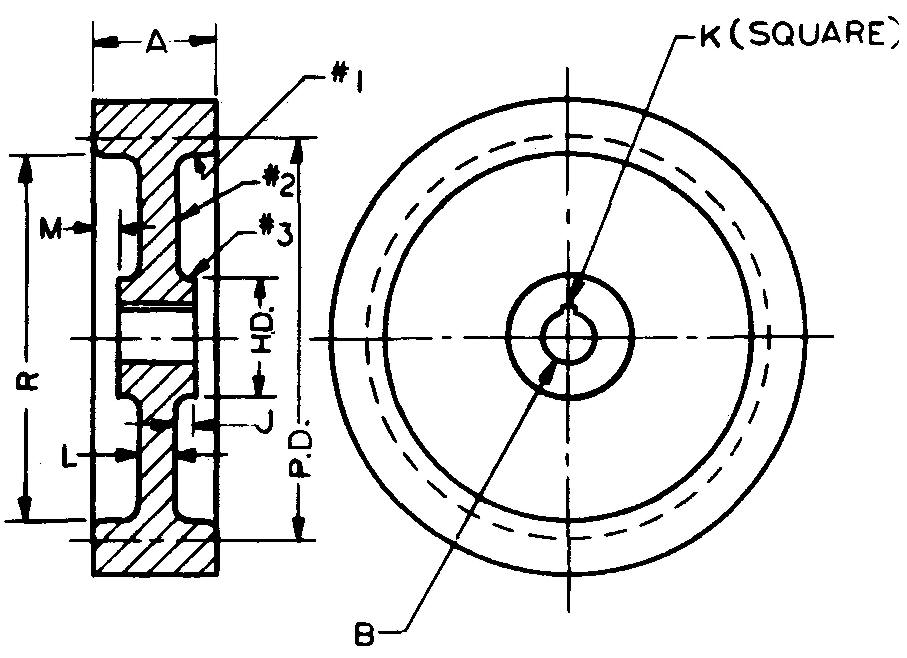

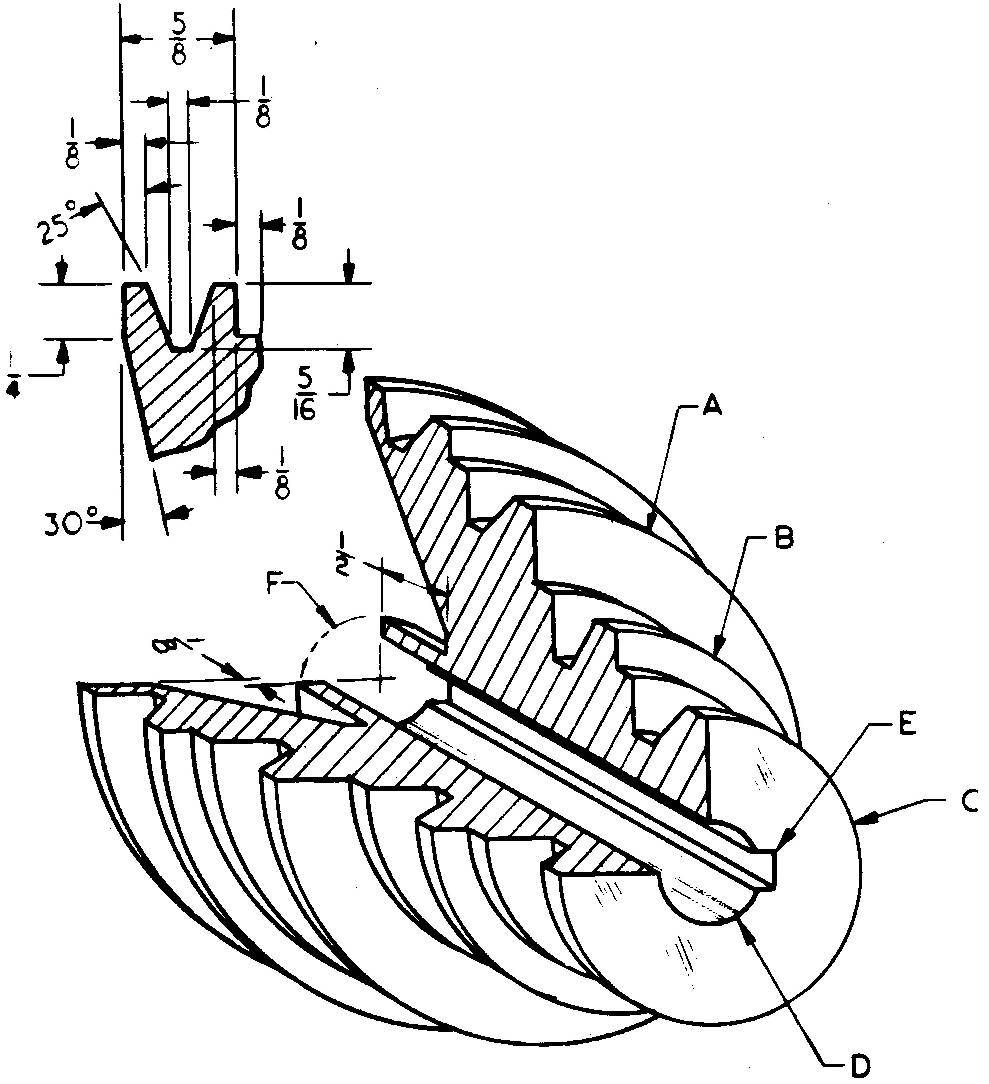

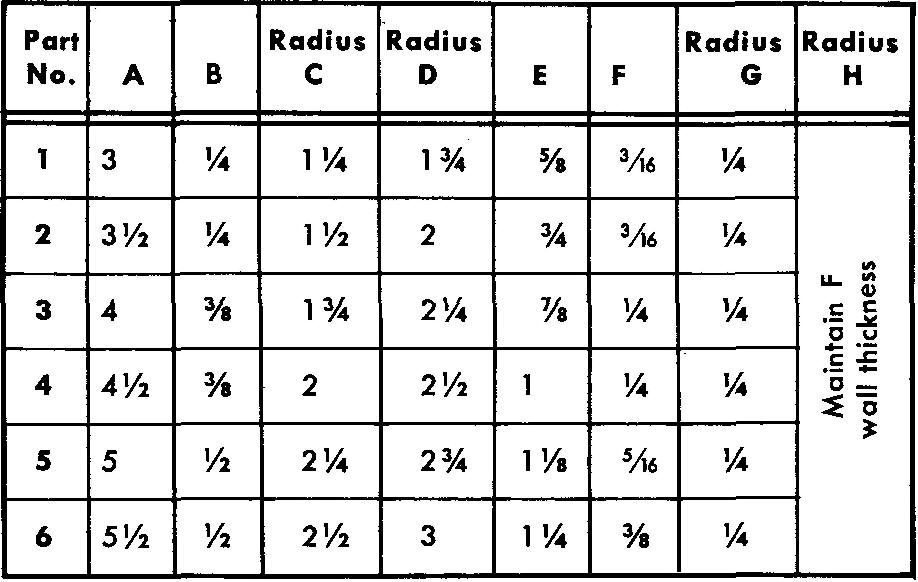

problem 14-20 sheave

Sheet Size Optional

Drawing Scale Optional

Material Bronze

Pieces per Unit 4

Casting Process Sand Casting

Finished Surfaces FAO except #1, #2, and #3

Required Finish Symbol f

References Sees. 8 (Figs. 8-21 and 8-22), 11, and 12 (Fig. 12-65); Table 56

Draw Parts 1 through 4 as directed.

Show grooves.

Full-sectional view required.

Specify "Remove all sharp corners."

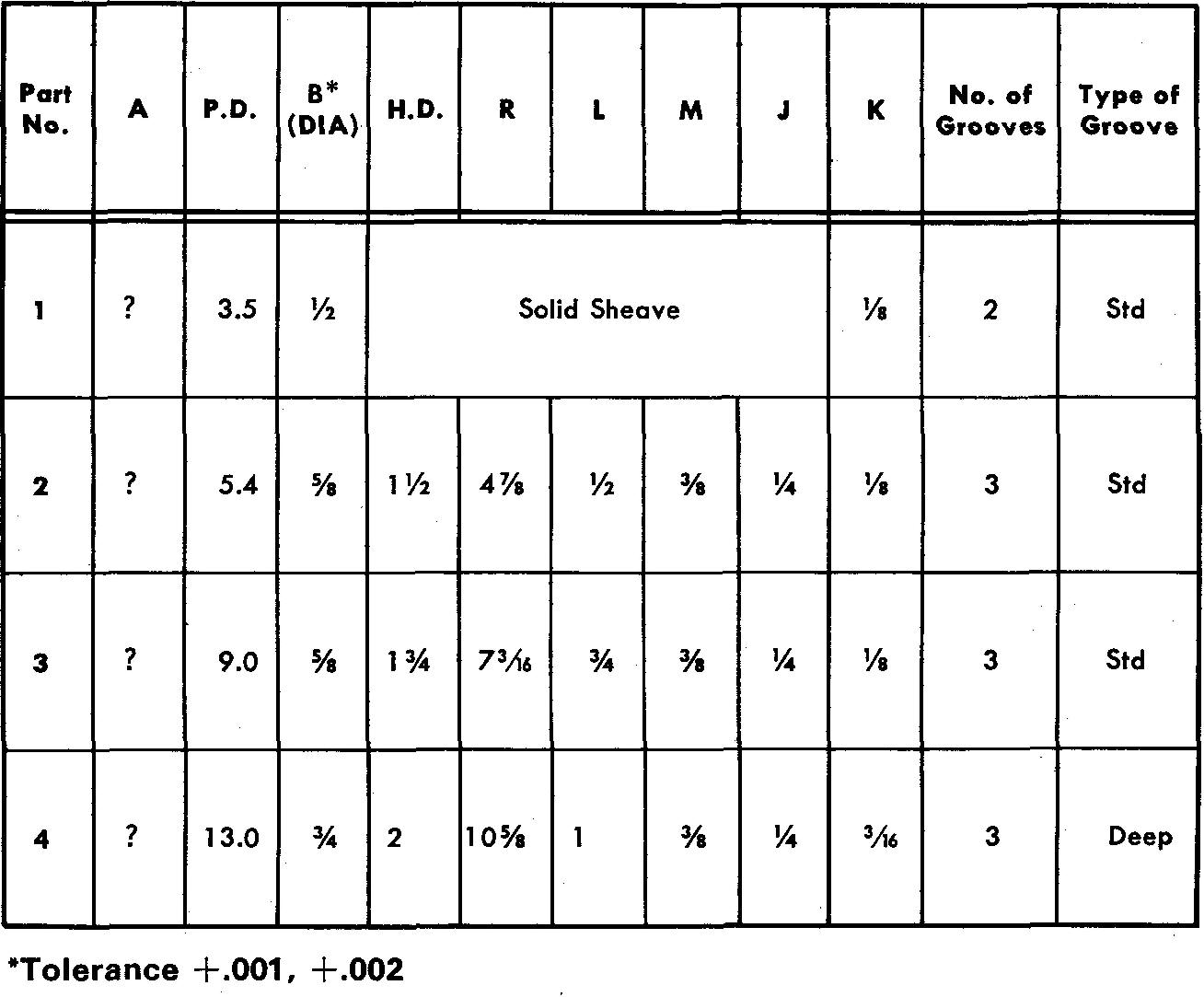

problem 14-21 hand wheel

Sheet Size 11x17

Drawing Scale Full

Material Gray Cast Iron

Pieces per Unit 1

Final Part Size 9-1/40D

Casting Process Sand Casting Finished

Surfaces Hub ends only Required Finish Symbol /

References Sees. 8 (Figs. 8-21 and 8-22), 12 (Fig. 12-48), (Fig. 12-65), and (Hub; Fig. 12-71); Tables 6 and 48

Barrel tumble finish.

Full-and revolved-sectional views required

A — Ream for 1" dia shaft, install 1/4 square key

B — 3/8 ream through, locate 3-1/4 from center hole

C — 6 dia

Spokes — Rectangular cross section, 1/2 x 1"

Hub — 2 dia x 1-3/4 lg, ends centered with rim

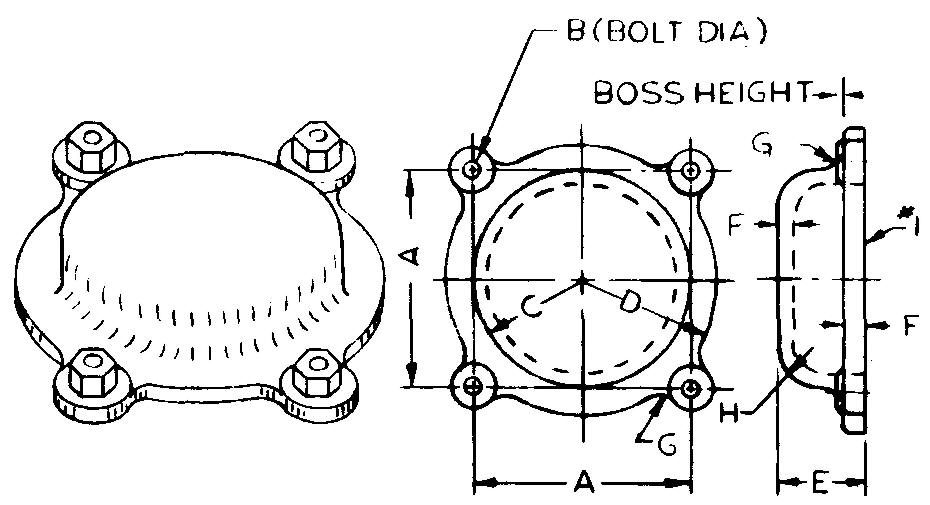

problem 14-22 connecting flange

Sheet Size 8-1/2 x 11

Drawing Scale Full

Material Gray Cast Iron

Pieces per Unit 1

Final Part Size 3-1/4 dia x 19/32 lg

Casting Process Permanent Mold

References Sees. 11 and 12 (Fig. 12-21); Table 14

Half-sectional view required.

A — 1-5/32 dia hole B — 1-7/8 dia

C — 2-1 /8 dia, tolerance +.001, +.002

D — 1/8R

Holes — Drill and counterbore for 1/4 socket-head cap screws, 4 required, equally spaced on 2-5/8 BC

problem 14-23 pressure plate

Sheet Size 8-1/2x11

Drawing Scale Half

Material Aluminum #43

Pieces per Unit 1

Casting Process Sand

Casting Finished Surfaces #1, #2, and #3

Required Finish Symbol f

References Sees. 8 (Figs. 8-21 and 8-22), 11, 12 (Fig. 12-6), (Fig. 12-42), and (Flange; Fig. 12-70); Table 8

Specify "Surfaces #1 and #3 must be parallel within +0.002 T.I.R.

Fillets and rounds 1/8 R."

A — 1 /4-20 UN?-2 threads, locate as shown, 1 /2 in from surface #3

B — 1.1875 dia bore, tolerance ±.002, 1-1/16 deep

C — 2-1/4 dia x 1-3/16 Ig to flange

D — 8-11/16 dia x 5/16 thick

Ribs — 1 /4 thick, 4 required, equally spaced

problem 14-24 coupling

Sheet Size 8-1 /2 x 11

Drawing Scale Full

Material Dow Metal R

Pieces per Unit 1

Final Part Size 5-11 /16 lg

Casting Process Die Casting

References Sees. 11 and 12 (Figs. 12-51 and 12.52)

A removed-sectional view is required.

A — .875 dia hole, tolerance -.003, -.004

B — 2-5/32 dia x 13/16 lg

C — 11/16 R x 3-1/4 lg

D — 2-1/32 dia x 1-1/16 lg

Slot — 3/16 deep x 11/16 wide x 2-5/16 lg

End holes — 1-3/8 dia x 7/16 deep, both ends

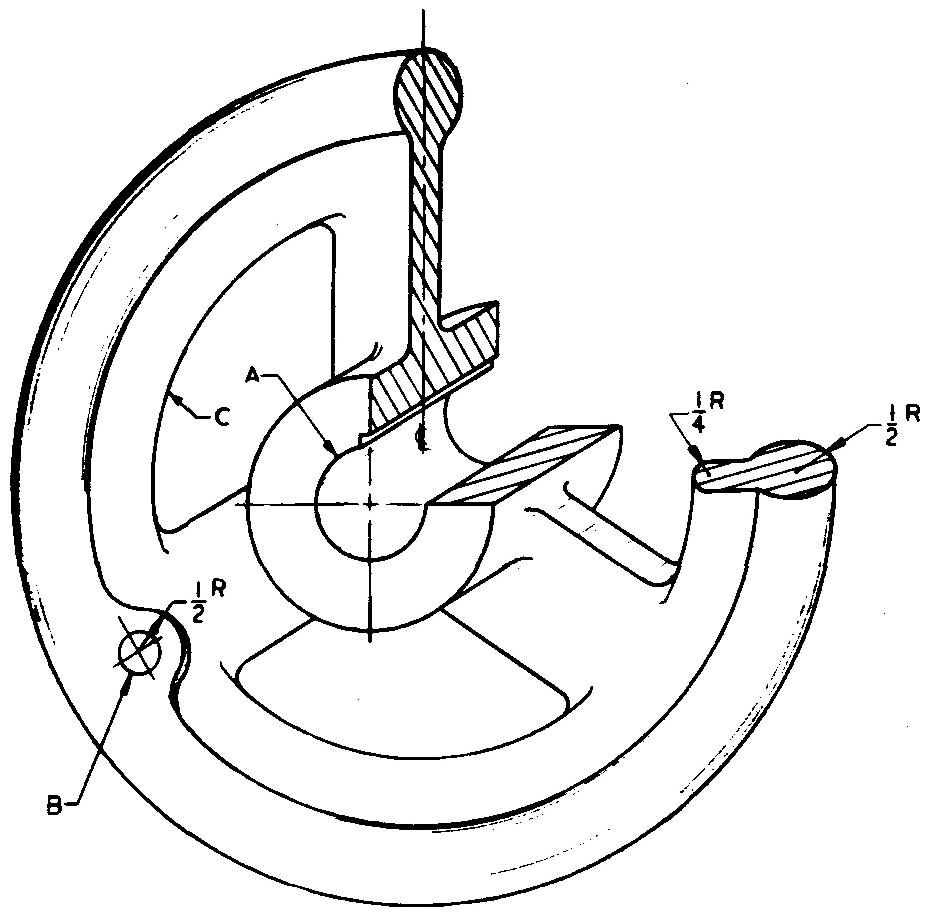

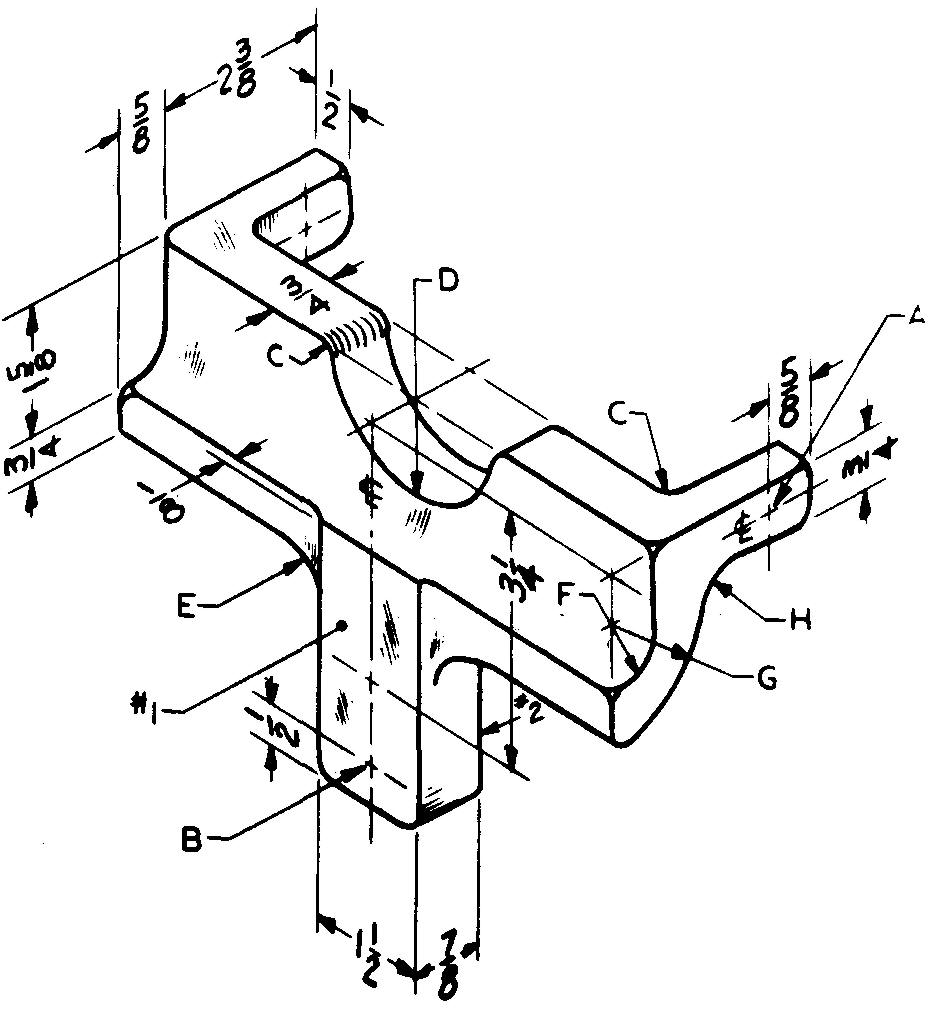

problem 14-25 pulley housing

Sheet Size 8-1 /2 x 11

Drawing Scale Full

Material Aluminum #43

Pieces per Unit 1

Casting Process Sand Casting

Finished Surfaces #1, #2, and base

Required Finish Symbol f

References Sees. 8 (Figs. 8-21 and 8-22), 12 (Fig. 12-6), 12 (Fig. 12-25), and (Fig. 12-48); Table 13

A — 11 /16 ream through, 1-3/8 bore, 7/8 deep 2 required in line, one from each side, locate 5-3/4 up from base on center with 7-1 /2 dimension

B — Clearance drill and spotface for 3/8 hexagonal bolts, 4 required, locate 4-1 /4 and center to center

Base size — 1" thick x 5-3/4 wide x 8-1 /2 lg

Inner walls extend down to form the base opening

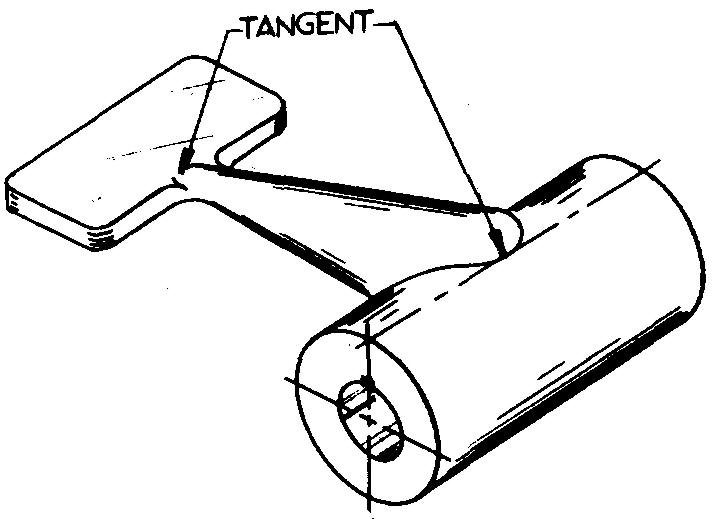

problem 14-26 special connector

Sheet Size 11x17

Drawing Scale Optional

Material Aluminum B 195 Pieces per Unit 2

Casting Process Permanent Mold

Finished Surfaces Ends of dias A, B, and C

Required Finish Symbol f

References Sees. 8 (Fig. 8-2 and 8-22) and 11

A half-sectional view is required.

Specify "Diameters A and E must be concen trie with ±0.002 T.I.R."

A — 4-1/2 dia x 1/4 thick

B — 1-11/16 dia

C — 3-1/2 dia

D — 3-1/16 dia

E — 1-1 /16 dia hole, tolerance -.0020, -.0025

problem 14-27 special cone pulley

Sheet Size 8-1/2 x 11

Drawing Scale Optional

Material Aluminum #43

Pieces per Unit 3

Final Part Size 4 dia x 2-1/2 lg

Casting Process Sand Casting

Finished Surfaces FAO

References Sees. 10, 11, and 12 (Fig. 12-65); Table 48

Full-sectional view required.

Calculate and show on drawing the width dimension at top of V groove.

A — 3-1/2 dia

B — 2-1/2 dia

C — 2 dia

D — 5/8 dia hole, tolerance ±.005

E — 1/8 square key

F — 1" dia problem 14-28 handle

problem 14-28 handle

Sheet Size 8-1/2 x 11

Drawing Scale Full

Material Aluminum #43 Casting

Pieces per Unit 1

Process Die Casting

References Sec. 12 (Fig. 12-48)

A — 1/8 ream at assembly with shaft

B — 3/8 dia hole (as cast)

C — 3/4 dia, one side only

Ribs — 1/8 thick x 13/16 wide x 13/16 lg

problem 14-29 sander table

Sheet Size 11x17

Drawing Scale Optional

Material Aluminum #13

Pieces per Unit 1

Final Part Size 7/8 thick x 12-1/2 lg

Casting Process Die Casting

References Sec. 12 (Fig. 12-48)

Specify "Holes must be in line." Specify "Rounds 1/16 R maximum."

A — 1/2 ream, 3/4 deep

B — 3/8 ream, 2 required, locate 1/2 in from ends

problem 14-30 housing

Sheet Size 11x17

Drawing Scale Full

Material Aluminum #43

Pieces per Unit 1

Casting Process Sand Casting

Finished Surfaces Base pads only

Required Finish Symbol f

Heat Treatment Stress relieve

References Sees. 9, 10, 12 (Fig. 12-21), and (Fig. 12-25); Tables 4 and 14

Two drawings required:

1) A pattern drawing (1/8-inch machining allowance).

2) A machining drawing. Use a separate sheet for each drawing.

Calculate and specify the total weight. Disregard fillets and rounds.

A — Clearance drill and counterbore for 5/8 socket-head cap screws, 2 required, locatec 4-1/2 up from base

B — Clearance drill and spotface for 3/8 socket-head cap screws, 4 required

Center rib — 5/8 x 2-1/2, located central with uprights.

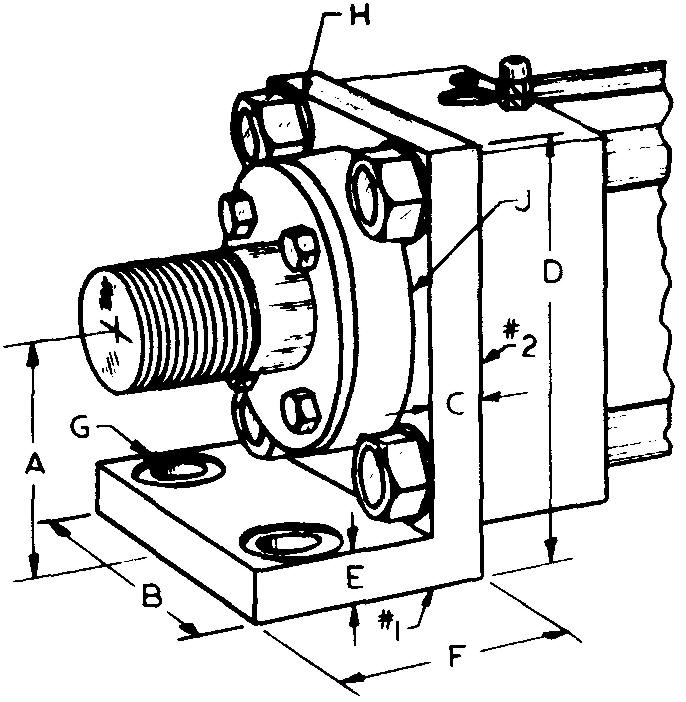

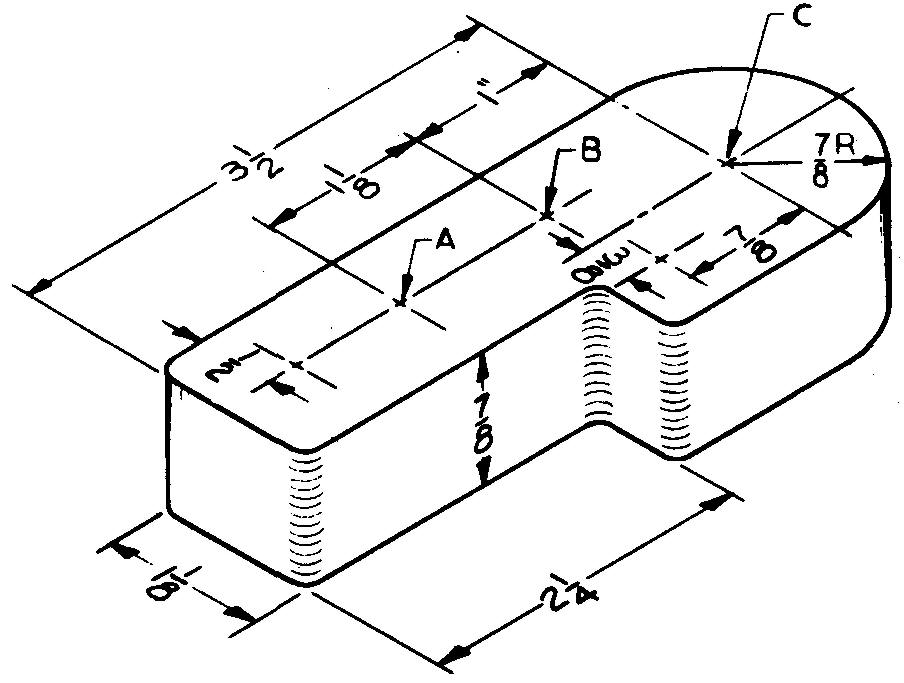

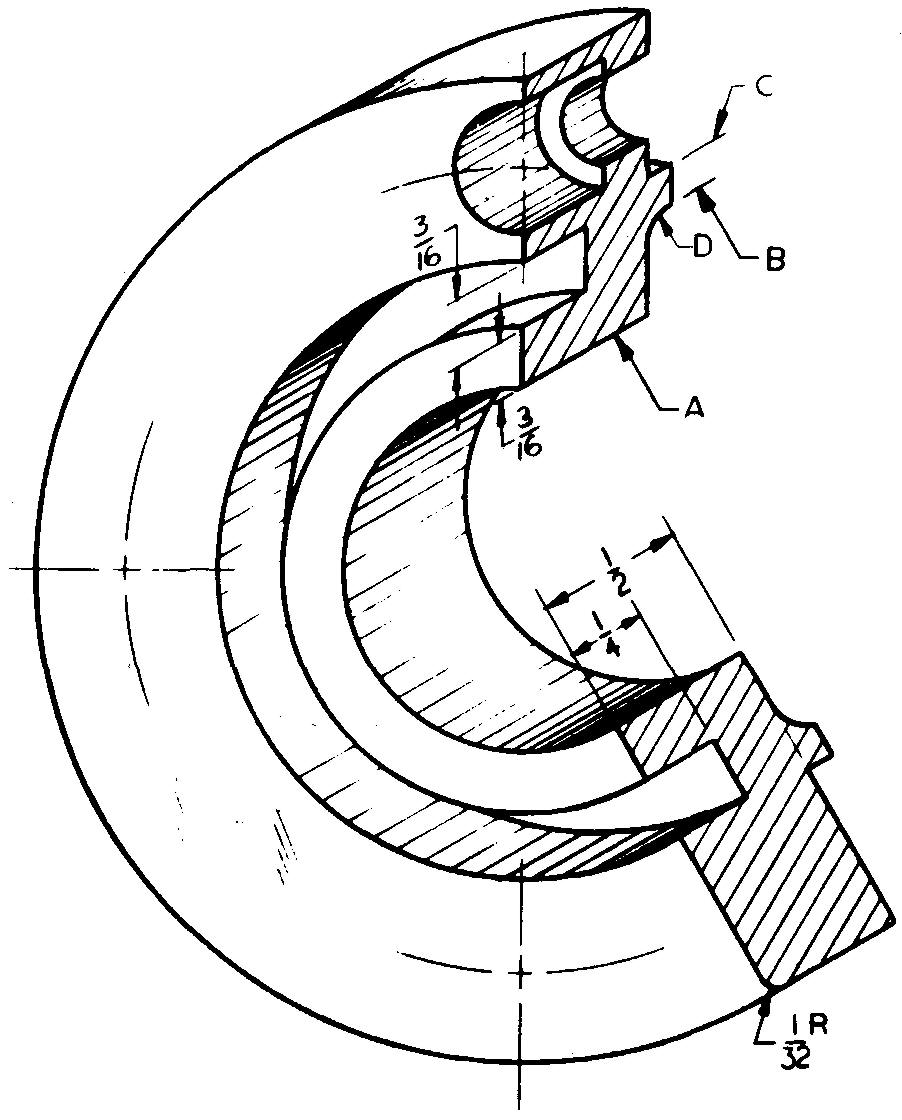

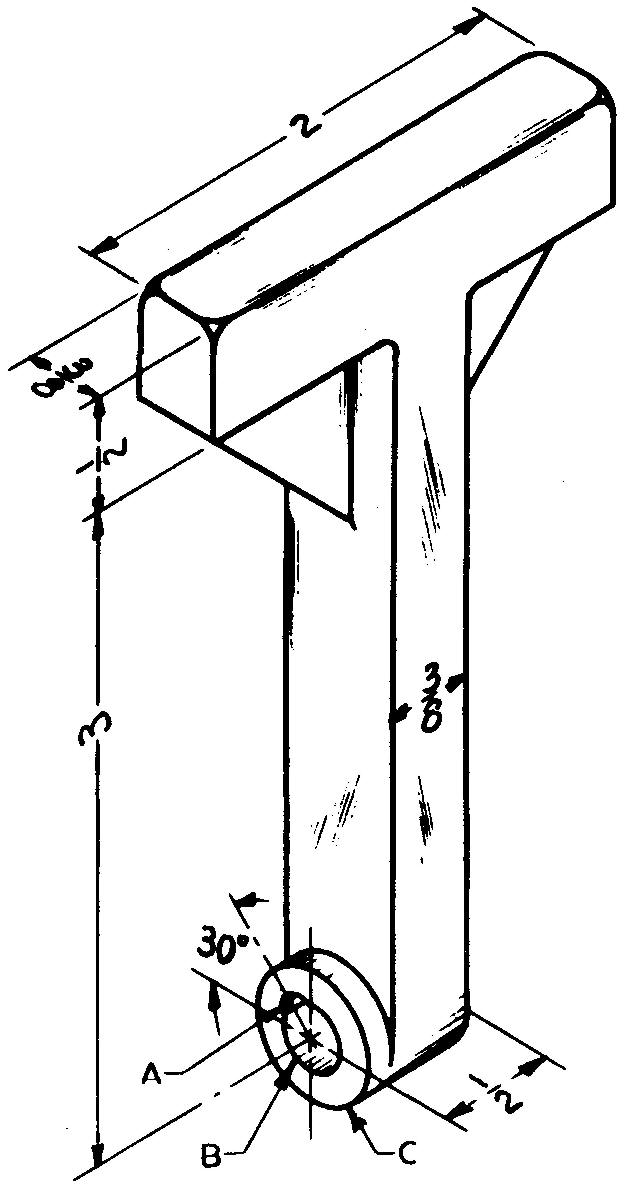

problem 14-31 pillow block

Sheet Size 11x17

Drawing Scale Twice

Material 1040 Steel

Pieces per Unit 2

Final Part Size 4 high

Casting Process Sand Casting

Finished Surfaces #1 and base

Required Finish Symbol f

Heat Treatment Normalize

References Sees. 9 (Normalizing), 11, 12 (Fig. 12.42), and 13 (Milling; Fig. 13-8); Tables 6 and 8 Parkerize finish.

A — Clearance drill for 1/4 bolts, 2 required, locate 3-3/8 center to center.

B — Clearance drill for 5/16 bolts, 2 required, 3 center to center

C — #5-40 UN ?-2 threads, 1/2 deep, 2 required (one hole on each side)

D — 3 dia

E — 2-5/16 dia, tolerance -.001, -.002, 5/8 deep

F — 2 dia, tolerance +.001, -.000, 1/16 deep

G — 1-1/4 dia, tolerance +.005

H — 4, central with base

Slots — below lugs (both sides), mill with 1-1/2 dia x 3/8 wide cutter, 1/2 deep measured from center line of hole A

Base size — 1/2 thick x 2 wide x 4 lg

problem 14-32 foot lever

Sheet Size 8-1/2x11

Drawing Scale Half

Material Gray Cast Iron

Pieces per Unit 1

Casting Process Sand Casting Finished Surfaces Hub ends only Required Finish Symbol V

References Sees. 8 (Fig. 8-4), (Figs. 8-21 and 8-22), 12 (Fig. 12-48), (Fig. 12-68) and (Hub; Fig. 12-71); Table 49

A revolved-sectional view is required. Hub —2 dia x4 lg Hole — 5/8 ream

Foot pad — 5/16 thick x 1-1/2 wide x 3 lg, coarse knurl top surface (as cast)

Distance from center of hub to end of foot pad - 8"

Cross section of lever arm — cylindrical

Install a keyway for a 3/16 gib-head tapered key

Fillets 1/4 R

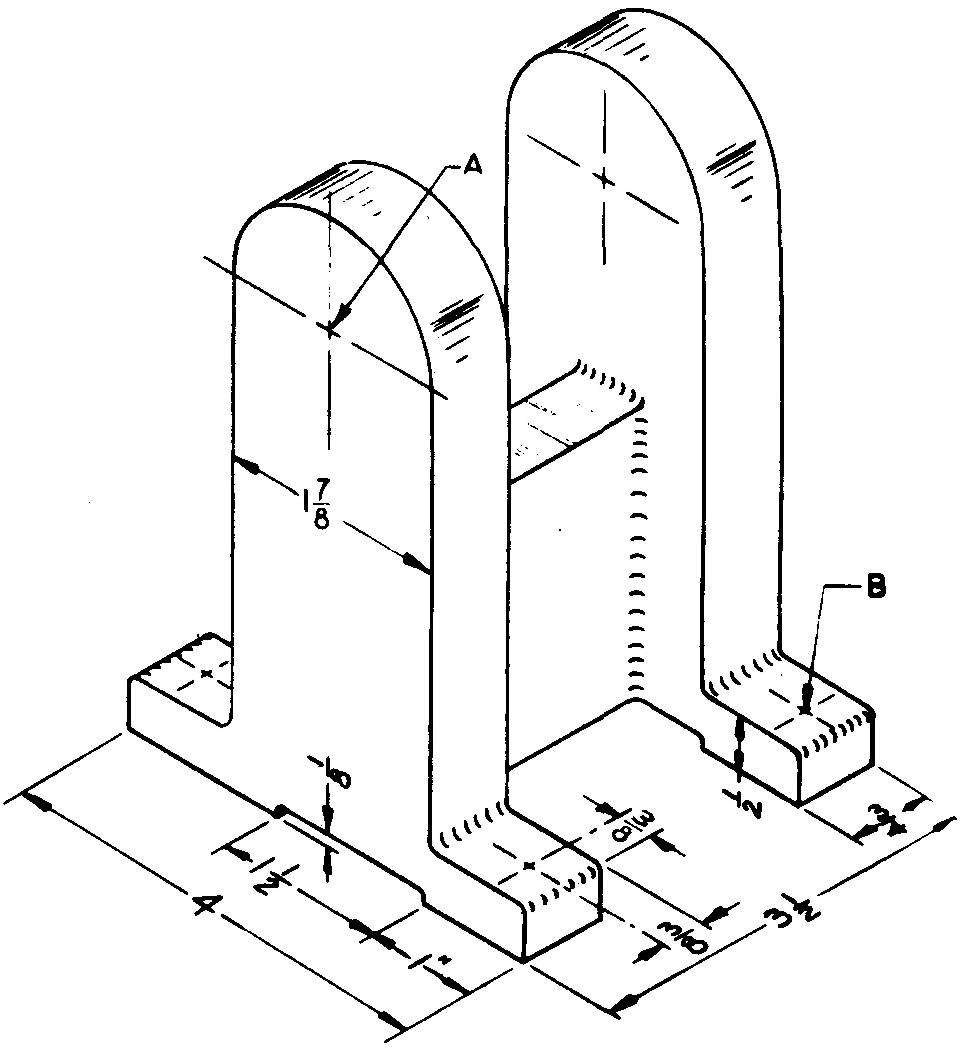

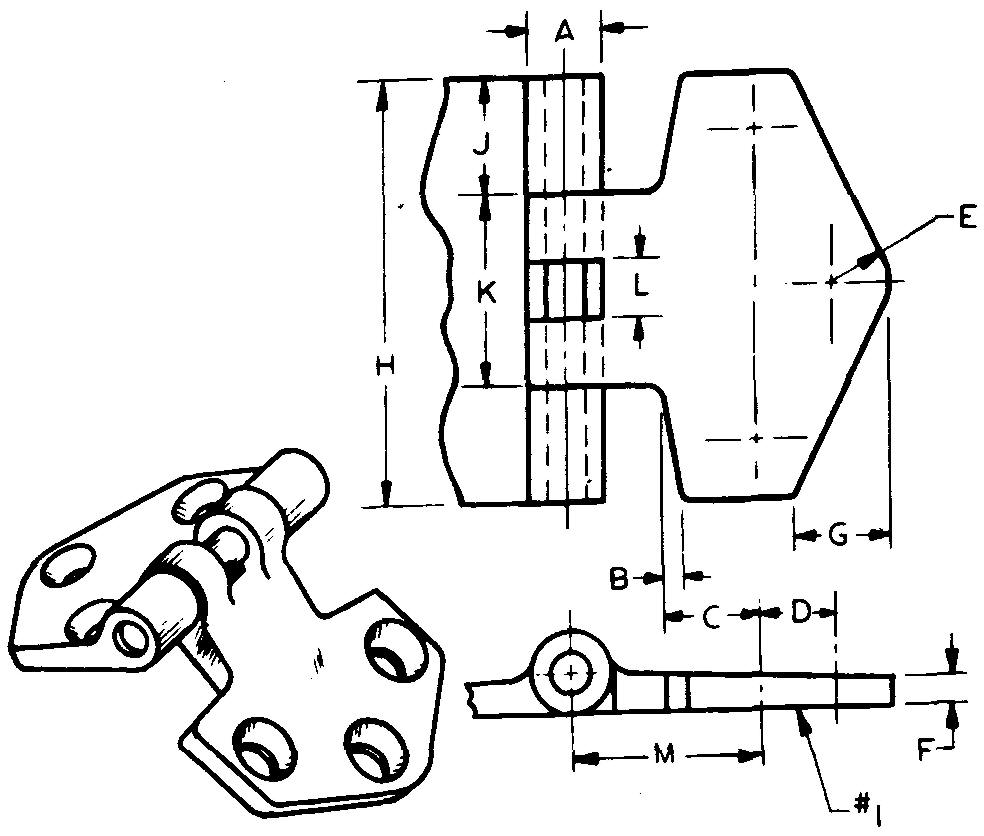

problem 14-33 hinge

Sheet Size 8-1/2x11

Drawing Scale Optional

Material Bronze

Pieces per Unit 4

Casting Process Sand Casting Finished Surfaces #1 and dimensions L and K Required Finish Symbol f

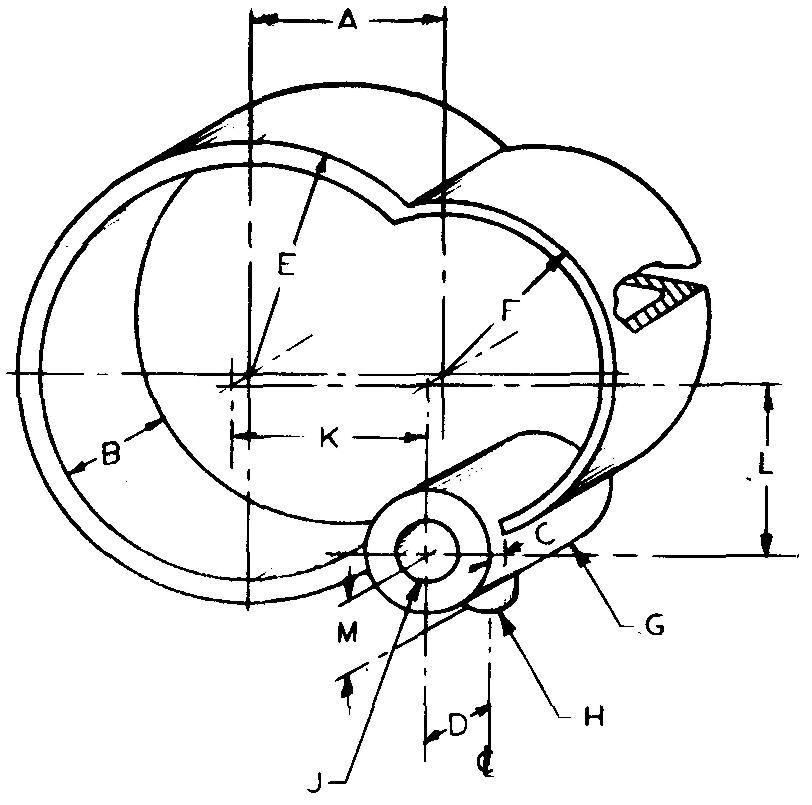

References Sees. 8 (Figs. 8-21

and 8.22), (Power Brushing; Fig. 8-25), 11 (Interference Allowance),

11,12

(Fig. 12-13), and (Fig. 12-48); Table 15 Power brush finish.

Draw views of both leaves on the same sheet.

A — 1 /2 dia

B — 1/8

C — 5/8

D — 1/2

E — 3/8 R

F — 3/16, top taper 5°

G — 5/8

H — 2-3/4

J — 3/4

K — 1-1/4

L — 3/8

M — 1-1/4

Clearance drill and countersink holes to fit 5/16 flathead machine screws, locate outer holes 2 apart.

Pinhole — ream with .001 clearance allowance for .249/.248 dia pin

problem 14-34 cover

Sheet Size 8-1/2 x 11

Drawing Scale Optional

Material Bronze

Pieces per Unit 1

Casting Process Sand Casting

Finished Surfaces #1 and boss surface

Required Finish Symbol f

References Sees. 8 (Figs. 8-21 and 8-22) and (Power Brushing; Fig. 8-25)

Power brush finish.

Draw Parts 1 through 6 as directed.

Select a suitable boss diameter. Boss height — 1/8

problem 14-35 frame

Sheet Size 11x17

Drawing Scale Optional

Material Aluminum #195

Pieces per Unit 1

Final Part Size 7-1/2 lg

Casting Process Sand Casting

Finished Surface #1

Required Finish Symbol V

References Sees. 8 (Figs. 8-21 and 8-22), 12 (Fig. 12-4), and (Fig. 12-48)

A — 3/8 ream, 2 required in line

B — Clearance drill for 3/8 bolts, 2 required locate 1-1/8 apart

C — 1/4R

D —1-1/4 R

E — 1"R

F — 5/8 R

G - 1-3/8 R

H - 1/2 R

Blend surface §2 and radius G with a 1/2 R arc and dimension accordingly.

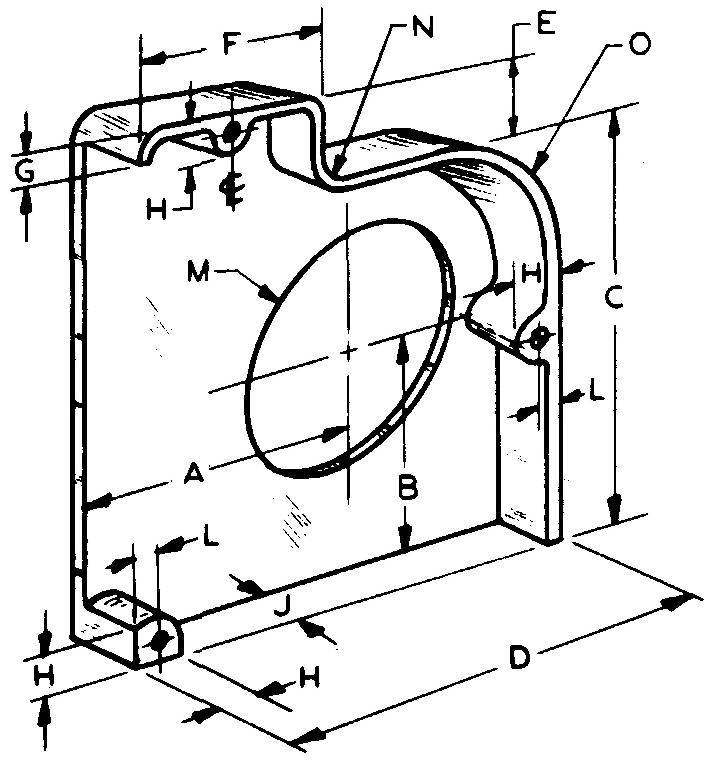

problem 14-36 gear casing

Sheet Size 11x17

Drawing Scale Full

Material Zamak #3

Pieces per Unit 2

Casting Process Die Casting

References Sec. 12 (Fig. 12-42); Table 8

A — 4

B — 3

C — 6-1 /2

D — 7-1 /4

E — 1 -3/4

F — 3-3/4

G — 1/2

H — 7/8

J — 1-1/2

L — 1 /2 (typical)

M — 3-3/4 dia

N — 1"R

O — 2R

Holes - 1/4-20 UN?-2, 3 required, 5/8 deep

Wall thickness — 1/4

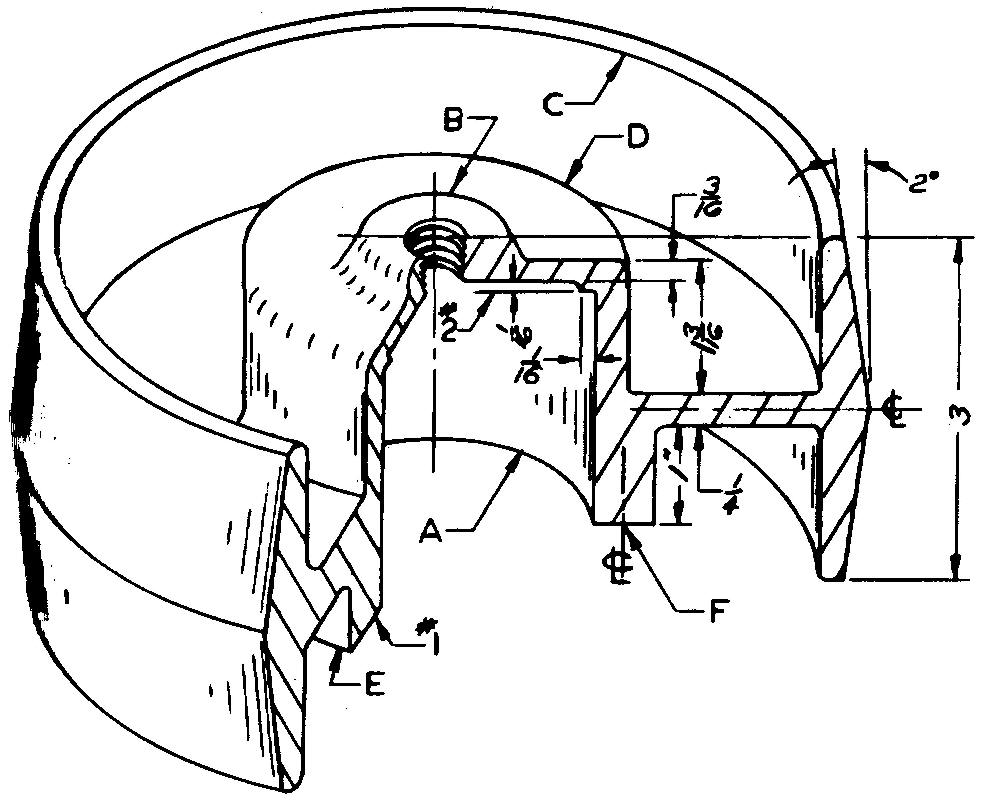

problem 14-37 pulley

Sheet Size 11x17

Drawing Scale Full

Material Gray Cast Iron

Pieces per Unit 2

Final Part Size 6 OD

Casting Process Sand Casting

Finished Surfaces #1, #2, and crown

Required Finish Symbol f

References Sees. 8 (Figs. 8-21

and 8-22), 11, 12 (Fig. 12-6), (Fig. 12-42), 12 (Crown; Fig. 12-74), and 20

(Fig. 20-11);

Tables 8 and 68

A full-sectional view is required. Specify "Fillets and rounds — 1/8 R."

A — 2-1/8 dia bore, tolerance +.0005, -.0000

B — 1-1/4 dia

C — 5-1/2 dia

D — 2-3/4 dia

E — 3-1/8 dia

F — 1/4-20 UN?-2 threads, 5/8 deep, 4 required, equally spaced on 2-5/8 BC Center hole — To fit 1/4 NPT

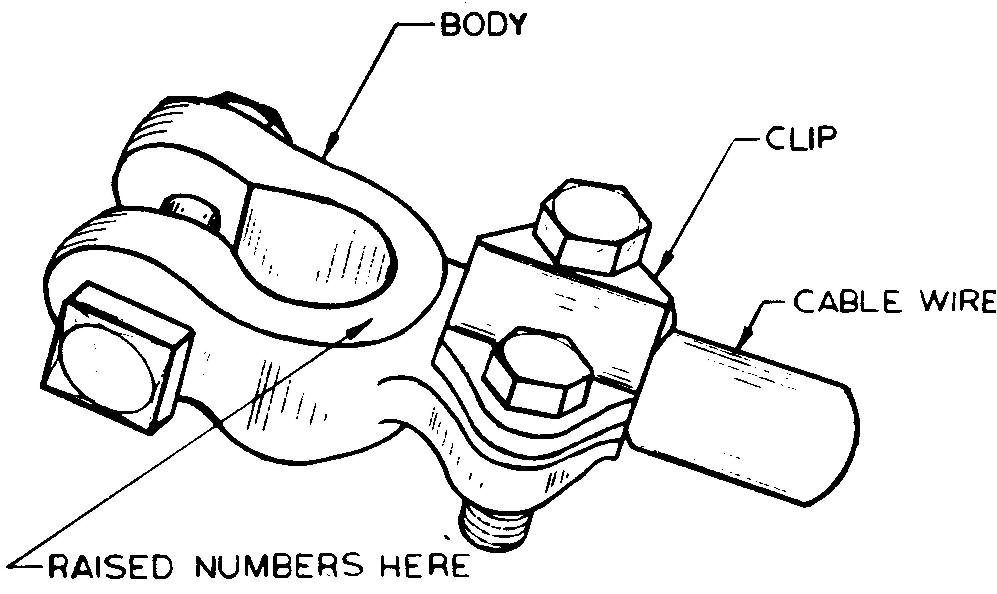

problem 14-38 battery terminal assembly

Sheet Size 8-1/2 x 11

Drawing Scale Full

Material Lead Total

Pieces Required 6 500

Casting Process Die Casting

References Table 13

Two details: 1) Body. 2) Clip. Draw views of both details on one sheet.

Specify "Body should be cast with raised numbers:

LK — 4385; give location dimension for the letter L;

each raised letter and number to be approximately 1/8 square by 3/64 high."

Estimate all omitted sizes and proportions.

The battery terminal (not shown) is 5/8 dia at large end and tapers 3° on a side.

Distance from the center of the terminal to the center of the 1/4 square-head bolt and nut — 1/2

Distance from the center of the terminal to the center of the 1/4-20 UN7-1 hexagonal-head bolts - 1-1/2

Bolts spaced 1" apart

Cable wire dia — 5/16

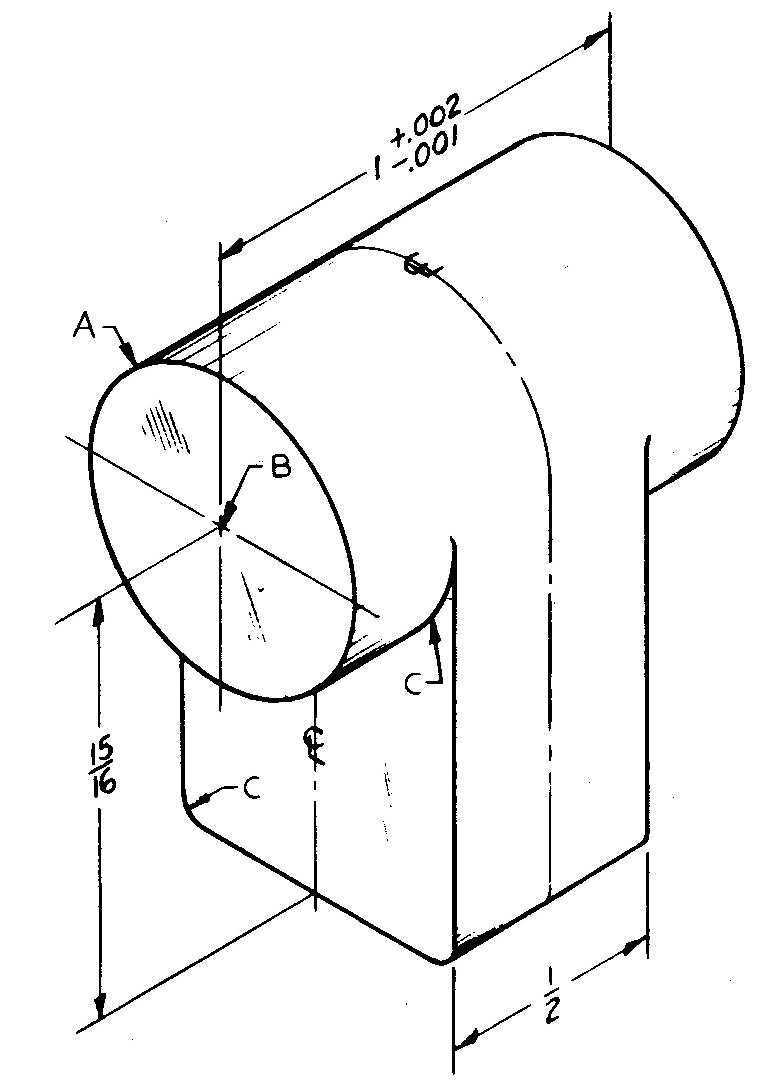

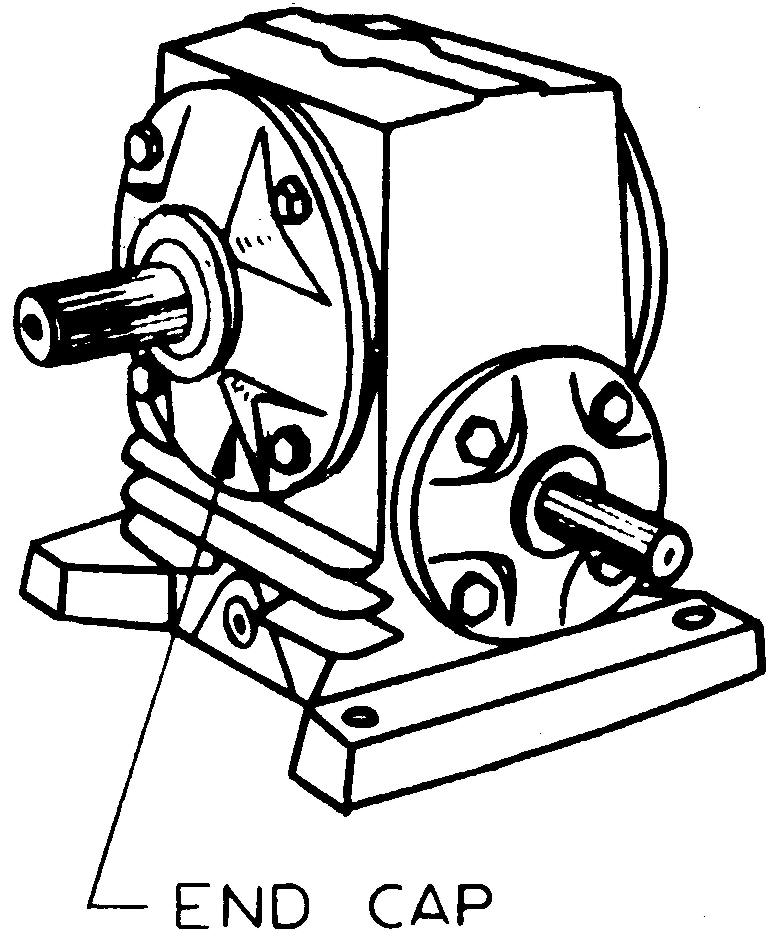

problem 14-39 end cap

Sheet Size 8-1/2x11

Drawing Scale Full

Material Gray Cast Iron

Pieces per Unit 1

Final Part Size 4-1/2 OD x 1-7/8 lg

Casting Process Sand Casting

Finished Surface #1

Required Finish Symbol V

References Sees. 8 (Fig. 8-21 and 8-22), 11, 12 (Fig. 12-25), and (Fig. 12-28), Tables 6 and 13.

Barrel finish before machining

Spotface the four equally spaced clearance holes on 3" BC, for 1/4 hexagonal cap screws

Ream center hole to 1 -1/8 dia, tolerance +.001, -.000

The rib sides are parallel and are formed by swinging 1/2R arcs from cap screw hole centers.

problem 14-40 pressure plate

Sheet Size 11x17

Drawing Scale Full

Material Ductile Iron

Pieces per Unit 1

Casting Process Sand Casting

Finished Surfaces #1, #2, #3, and #4

Required Finish Symbol V

References Sees. 8 (Figs. 8-21 and 8-22), 11, 12 (Fig. 12-25), and 12 (Flange; Fig. 12-70); Table 14

Specify "Center hole must be concentric with 1-3/4 dia within ±0.002 T.I.Ft."

A — 1/4

B — 1-1/8

C — 1-7/8

D —1-1/2

E — 2-1 /4 dia, tolerance -.002, -.003

F — 1-3/4 dia, tolerance ±.0005

Flange — 7-1/4 dia x 3/8 thick

Center hole — 1-1/4 dia, tolerance +.0005

Holes — 13, equally spaced on 6-1/8 BC

clearance drill and spotface for 1 /4 socket-heac cap screws

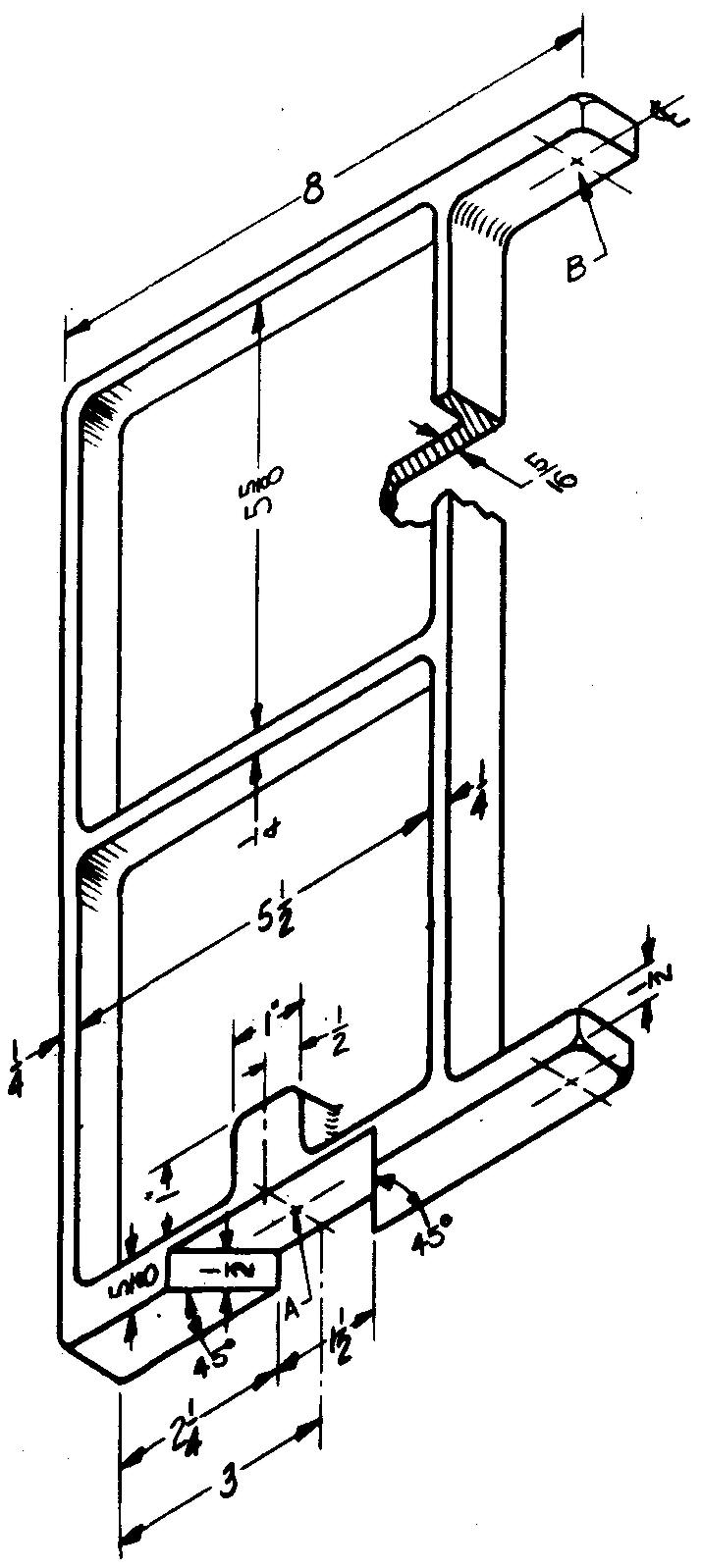

problem 14-41 bobbin chute

Sheet Size 11x17

Drawing Scale Full

Material Aluminum #13

Pieces per Unit 1

Casting Process Die Casting

References Sec. 12 (Fig. 12-42); Tables 6 and 8 Annodize finish.

A — 9

B — 7 (to sharp corner)

C — 1-1/2

D — 3

E — 3/16 (vertical measurement)

F — 1-1/2

G — 1-3/4

H — 3-3/4

J — 3/8-16 UN?-2 threads, through, 2 required, locate 1" apart

K — 1"

L — 3

Top pad — 3/4 thick with two 1/4 thick supporting ribs (not shown) on back surface (location and size to suit)

Walls — 1/4 thick

problem 14-42 cross slide

Sheet Size 8-1/2 x 11

Drawing Scale Full

Material Gray Cast Iron

Pieces per Unit 2

Casting Process Sand Casting

Finished Surfaces #1 through #8

Required Finish Symbol f

References Sees. 8 (Figs. 8-21 and 8-22), 10, 11, and 12 (Fig. 12-19)

A full-sectional view is required.

Calculate and specify over rolls dimensions (0.250 dia rolls) for dovetail.

A — 5/16 drill, 1/2 dia reverse counterbore, 1/8 deep

B — 2-1/2 dia

C — 1-1/4 dia

D — Center slot 5/8 wide

problem 14-43 drill head

Sheet Size 11x17

Drawing Scale Full

Material Gray Cast Iron

Pieces per Unit 1

Final Part Size 4-5/16 lg

Casting Process Sand Casting

Finished Surfaces #1, slot, and boss ends

Required Finish Symbol f

References Sees. 8(Figs. 8-21 and 8-22), 11 (Interference Allowance), (Fig. 12-4), 12 (Fig. 12-48), and 13 (Milling; Fig. 13-8)

A — 1/2 ream through

B — 1/8 drill through, 2 required, locate 3/4 apart

C — 1/8 drill, 2 required in line

D — 3/4 dia bore, tolerance +.0015, -.0005, 2 required in line

E — 5/8 ream, 2 deep

F — To fit .500/.499 thick mating part with .0015 clearance allowance

G — 7/8 R cutter, 1/8 wide (central with 1/2 dimension)

H — 1-1/2R

J — 9/16R

K — 1/2R

Hole locations:

From hole A to hole D —6

From hole E to hole D — 3

From hole C to hole D — 2

problem 14-44 gear guard

Sheet Size 11x17

Drawing Scale Optional

Material Zamak #5

Pieces per Unit 2

Casting Process Die Casting

References Sees. 11 and 12 (Fig. 12-42); Table 8

A — 5

B — 1-7/8

C — 1/4

D — 1 -1/4 (to center line of boss H)

E — 4R

F — 3R

G — 2 dia x 2-1/2 lg

H — 1-1/8 dia boss, 5/16-18 UN?-3 threads to hole J

J — 1" dia hole, tolerance +.001, -.002

K — 3-3/8

L — 2-15/16

M — 1-1/4 (to end of boss H)

Wall thickness — 1/4

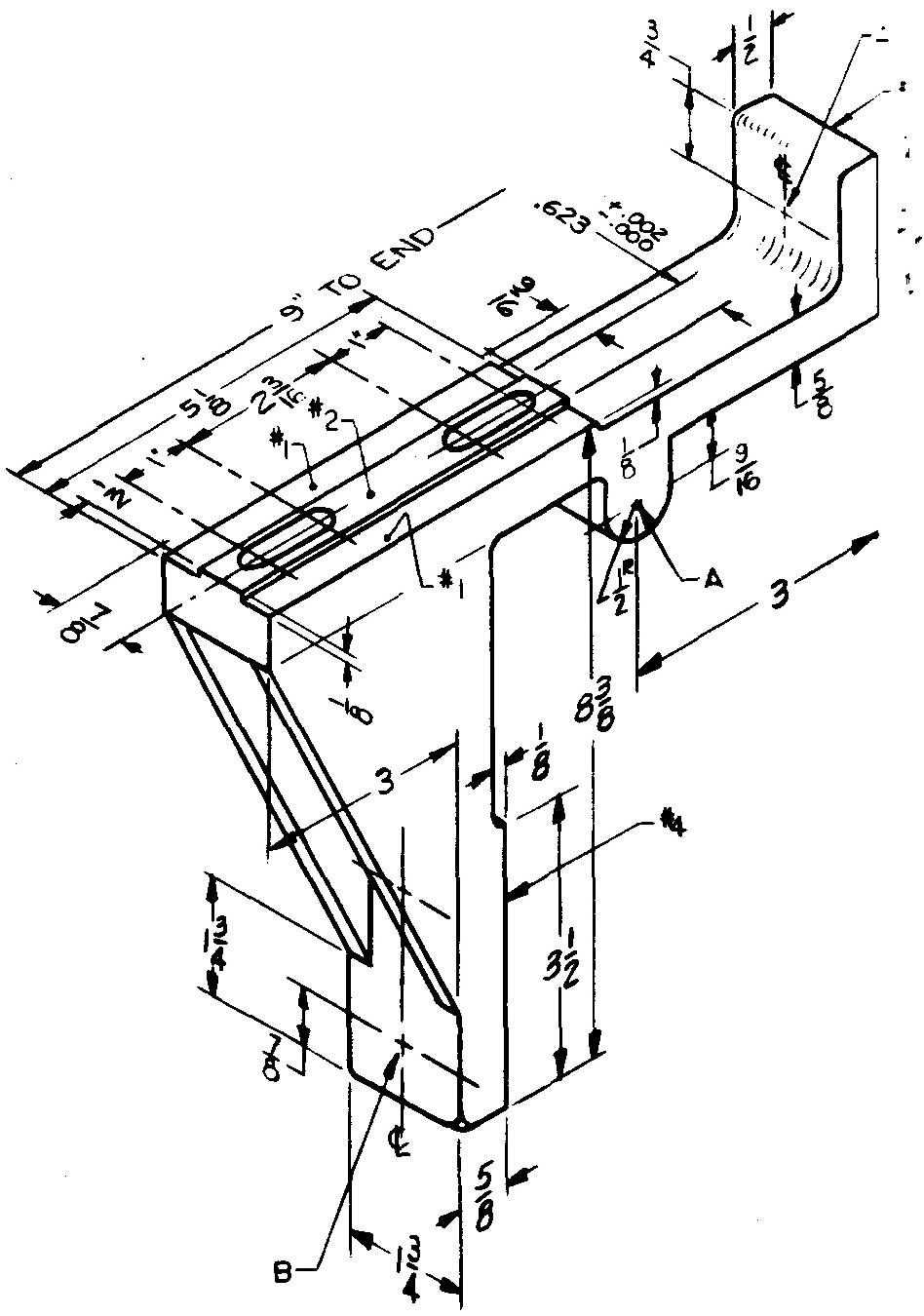

problem 14-45 bracket

Sheet Size 11x17

Drawing Scale Optional

Material Gray Cast Iron

Pieces per Unit 2

Casting Process Sand Casting

Finished Surfaces #1, #2, #3, #4, and 0.623 dimension

Required Finish Symbol V

Heat Treatment Stress relieve

References Sees. 8 (Figs. 8-21 and 8-22), 9, 11, 12 (Fig. 12-25), and (Fig. 12-48); Table 14

A — 5/8 ream, 2 required

B — Clearance drill and spotface for 5/16 socket-head cap screws, 2 required, locate 1-3/4 apart

Slots — Clearance to fit 5/16 bolts Ribs - 1/4 thick

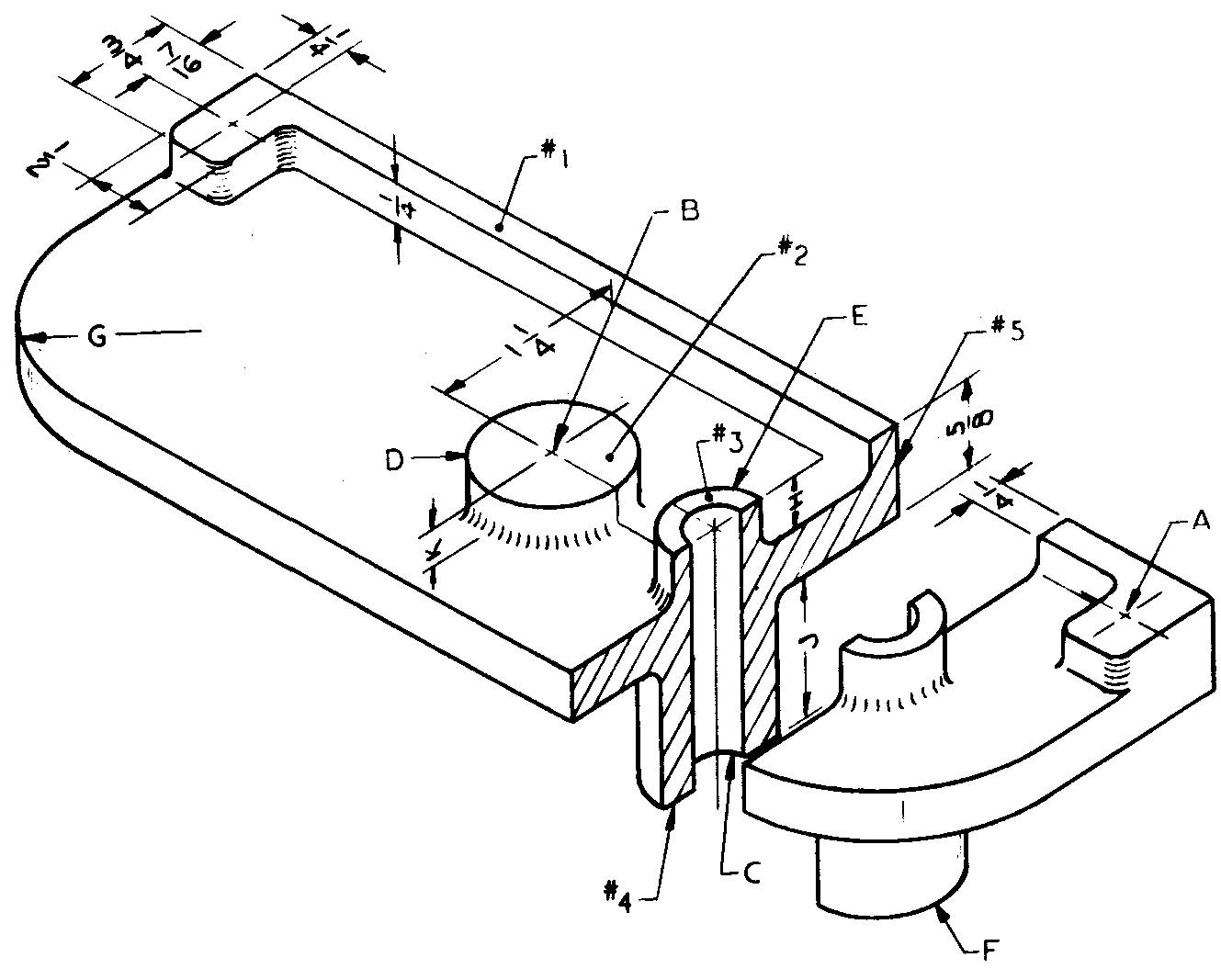

problem 14-46 bearing cap

Sheet Size 11x17

Drawing Scale Full

Material Brass

Pieces per Unit 1

Casting Process Sand Casting

Finished Surfaces #1, #2, and #3

Required Finish Symbol f

References Sees. 8 (Figs. 8-21 and 8-22), 11, 12 (Fig. 12-25), and 20 (Fig. 20-11); Tables 28, 34, and 68

Specify "Fillets and Rounds — 1 /8 R."

A — Clearance drill for 3/8 dia studs and spot-face for plain washers, vertical holes, 4 required locate 1-7/16 and 3-1/4 center to center

B — 1/8 NPT

C — 1-13/16 dia, tolerance +.0015

D — 1"dia

E— 2-3/4 dia

G — 9/16 R

H — Blend radius

J — 1/2

K — 1-1/2

problem 14-47 apron

Sheet Size 11x17

Drawing Scale Full

Material Cast Iron

Pieces per Unit 1

Final Part Size 2-13/16 wide x 6-3/8 lg

Casting Process Sand Casting

Finished Surfaces #1, #2, #3, #4, and #5

Required Finish Symbol V

References Sees. 8 (Figs. 8-21 and 8-22), 10, 12 (Fig. 12-42), and (Fig. 12-48); Tables 4 and 8

Calculate and specify the total weight. Disregard fillets and rounds.

A - 1/4-20 UN?-3 threads, through holes, 2 required

B — 5/8 ream through

C — 7/16 ream through

D — 1" dia, locate on common center line 1 -1 /4 from E

E — 3/4 dia, locate 1-9/16 from surface #5 and 1 -1/4 from near end

F - 1" dia G - 1 -1 /4 R, both ends

H-3/8 J-1"

K — 3/8 (top boss only)