The industrial drafting room

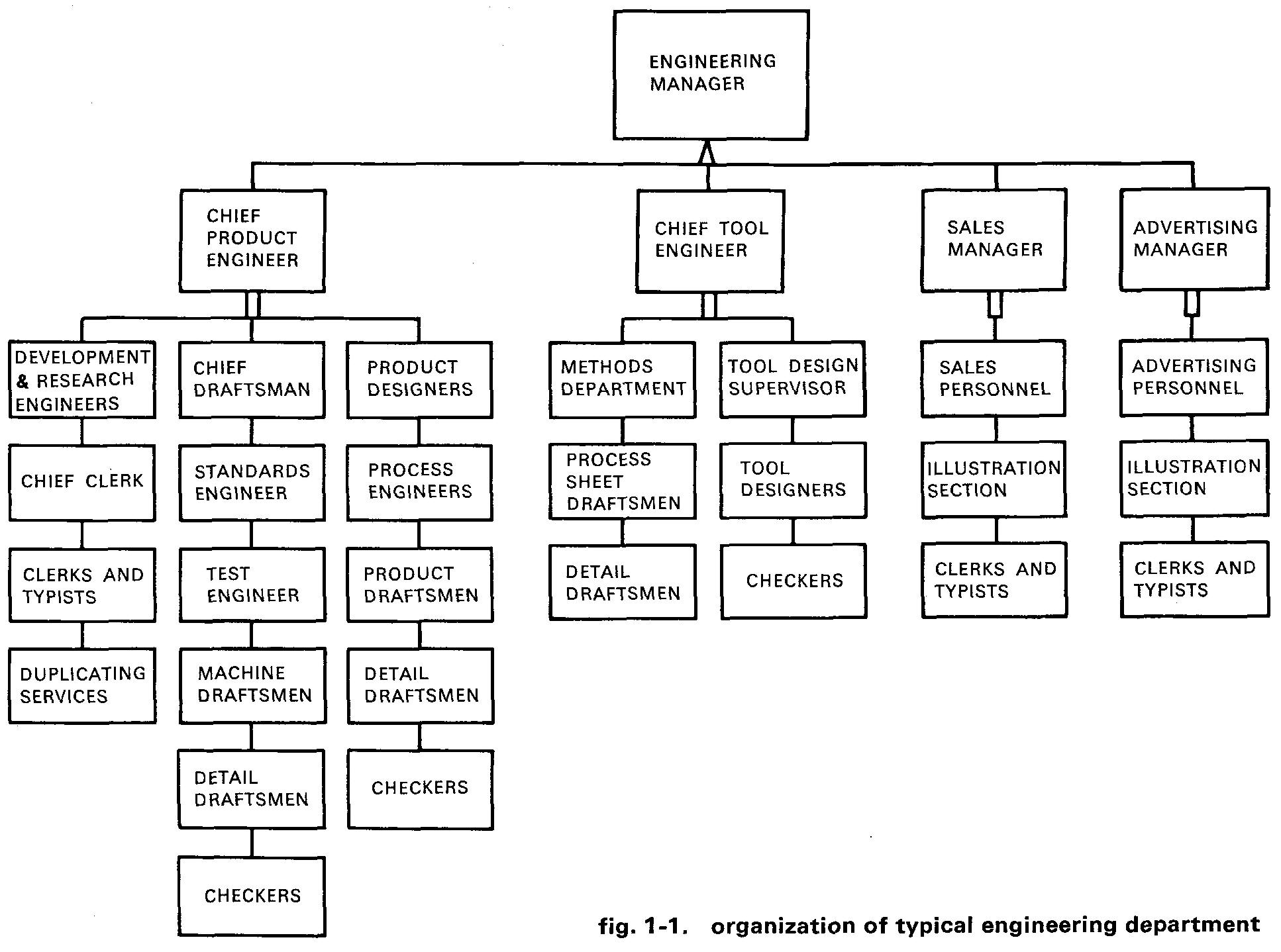

Figure 1-1 shows how a typical medium-to-large size engineering department is organized. To manufacture a product efficiently and economically requires a high degree of teamwork. Each person on the team should know as much about his job as possible.

He should also know, in general, something about the duties of others, particularly those in his own department.

The engineering manager directs the teams. Working closely with him are four department heads: the chief product engineer, the chief tool engineer, the sales manager, and the advertising manager.

These men meet regularly to decide what the company will produce. They also make all important decisions regarding the design, manufacture, advertising, and sale of the product.

The chief product engineer heads the department where the company's products are designed and drawn. These products may be single machine parts, whole machines, or large structures.

Sketches, calculations, and design layout drawings are made of the product. Detail drawings of each individual part of the product and drawings showing how the parts are assembled are made and checked for correctness.

Many job classifications come under this department.

Included are research and development engineers, process engineers, standards engineers, and test engineers; product designers; machine draftsmen, checkers, detail draftsmen, and product draftsmen; blueprinting personnel, and various other workers such as specification writers, clerks and typists, and so on.

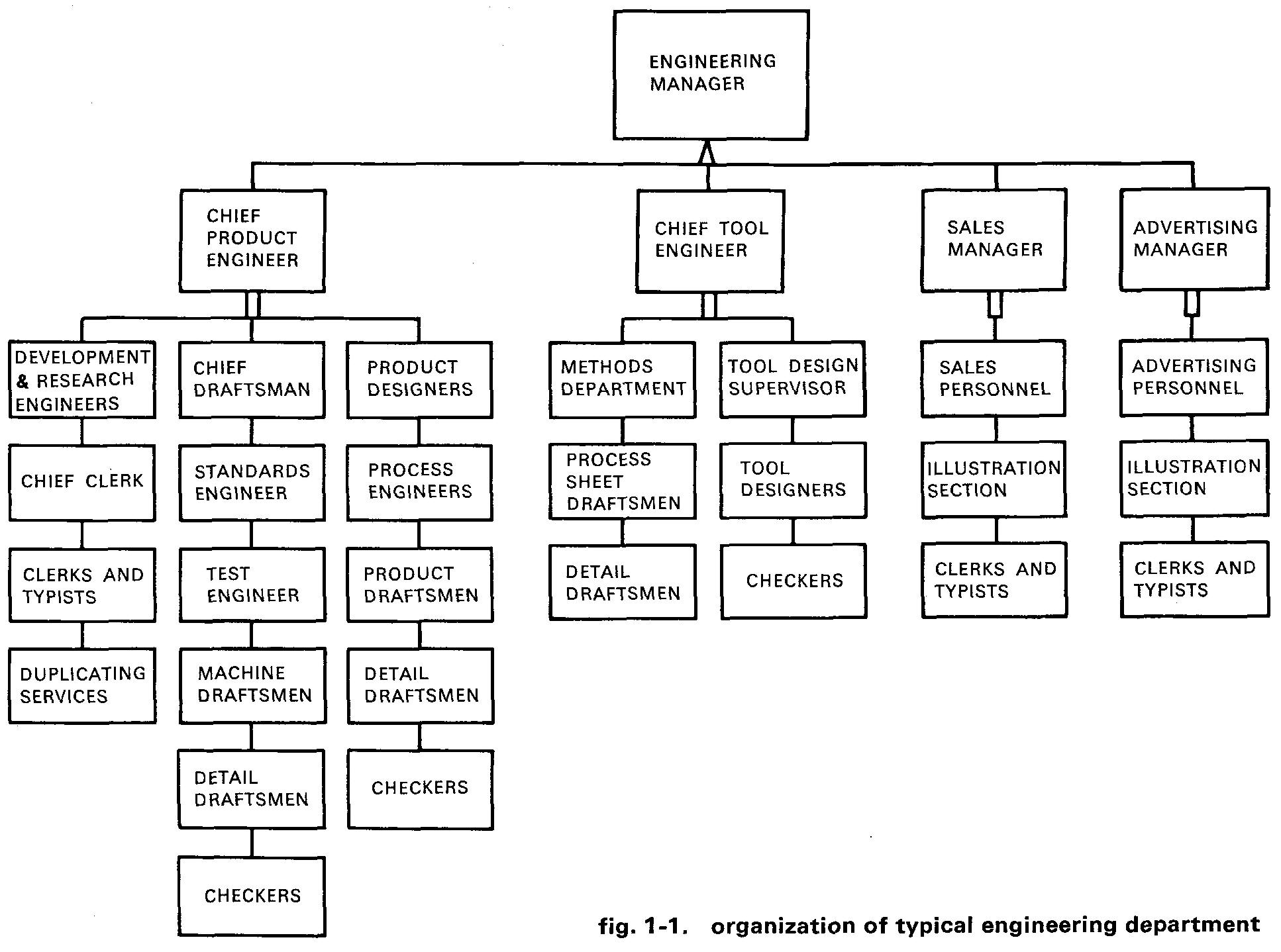

When a new machine is designed, the engineers frequently need to test the effectiveness of the various moving parts. To do this, they construct engineering models made of wood, metal, or other materials. The model may be of a single part or of a group of parts, depending upon the needs of the design.

Figure 1-2 shows a wood model of a portion of a textile machine.

Fig. 1-2. An engineering model

One or more prototypes or test models are often made when a new machine or structure is developed. Test engineers examine and perform various tests on the mechanisms in an effort to improve the design of the product. Prototypes of automobiles, aircraft, military weapons, automatic machinery, and so on are usually made prior to production.

Development, research, test, and process engineers usually work together to develop production schedules, operation sheets, listings of available machinery, and other information necessary for the manufacture of the product.

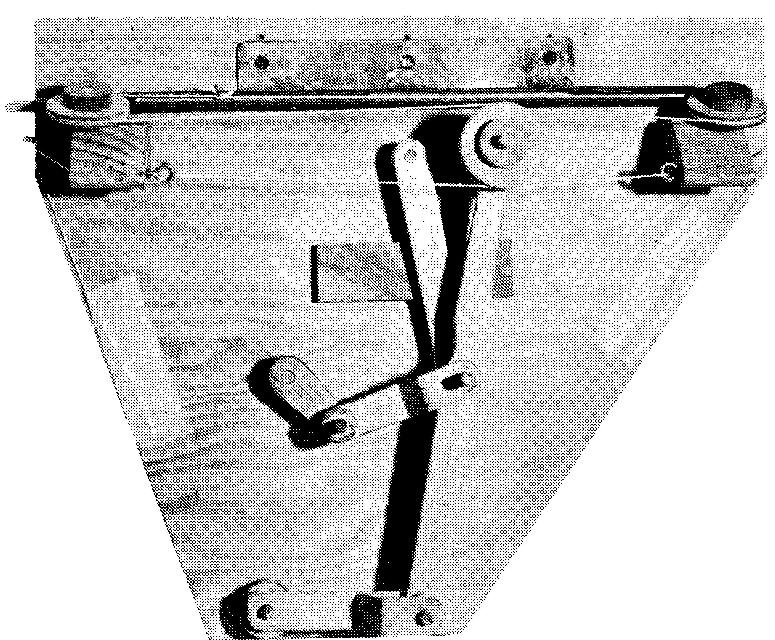

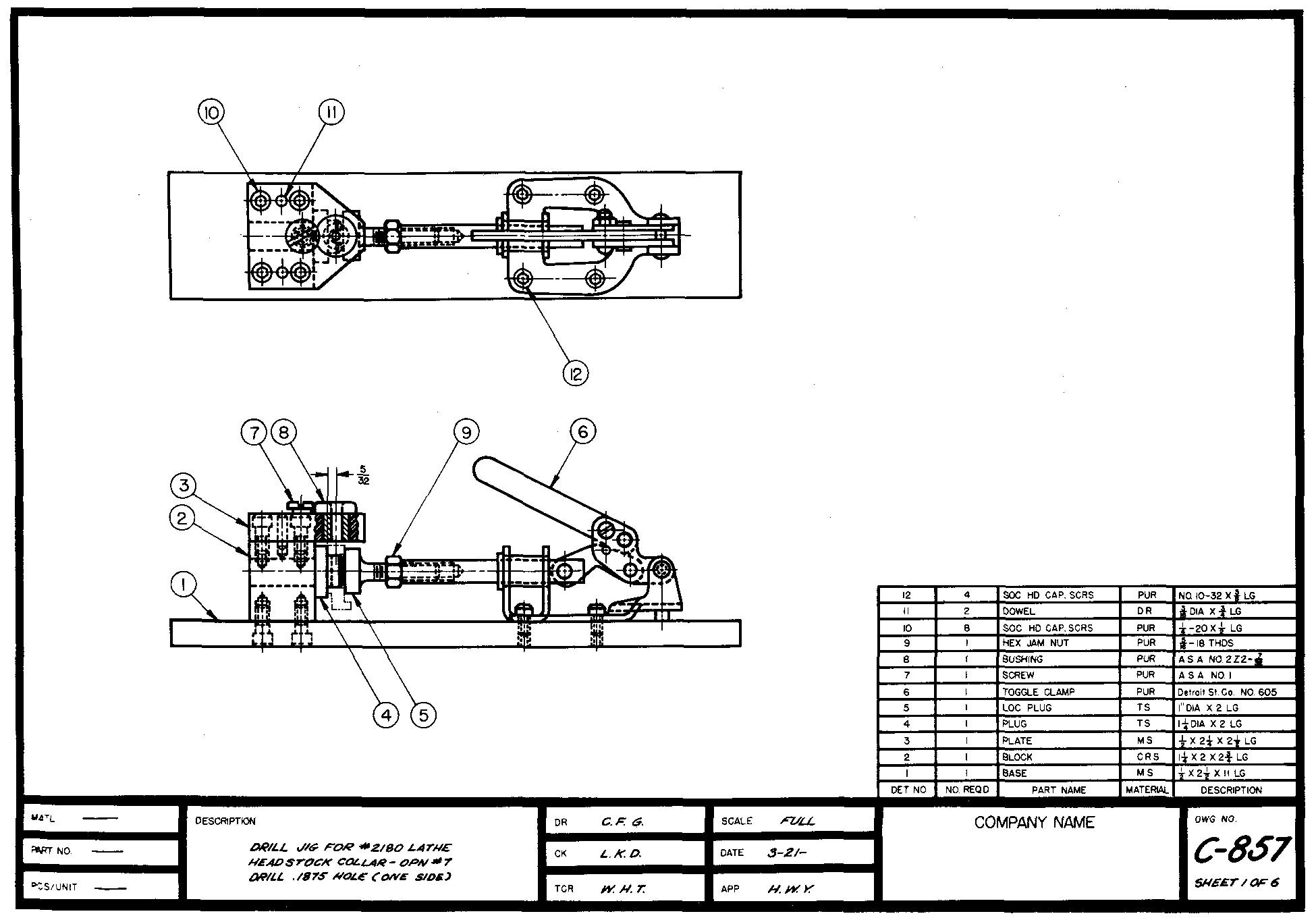

A typical product drawing is shown in Fig. 1-3.

Fig. 1-3. A product drawing

The abbreviations used in this drawing are listed in Table Standard abbreviations.

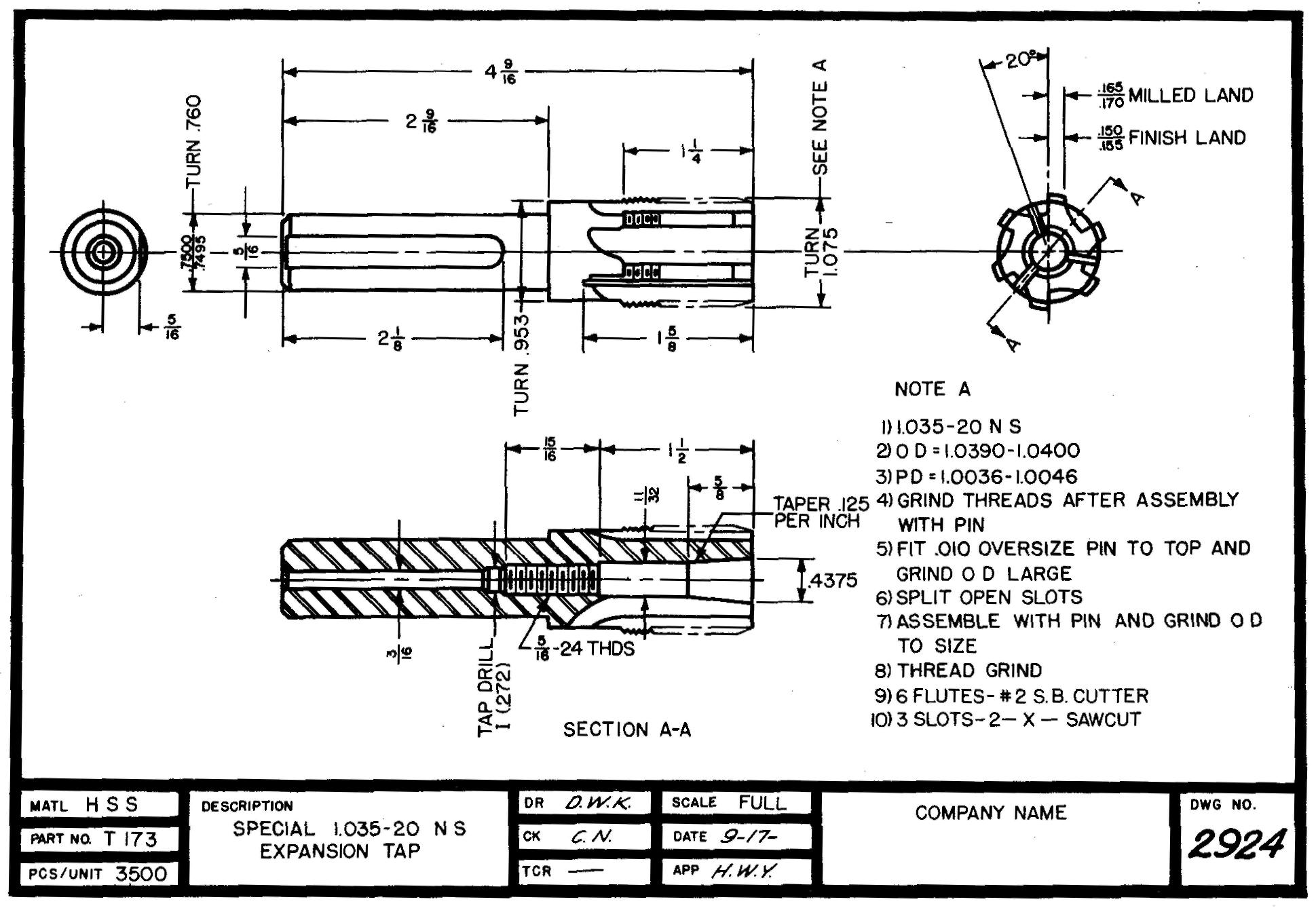

The tool design department, headed by the chief tool engineer, works from the product drawings. Here, important decisions are made regarding the design and drawing of special tools, gages, and jigs and fixtures which may be needed to manufacture the various parts of a machine or structure in the shop.

Special tools include a wide variety of cutters and tool bits which are frequently required to make machine parts. Gages are devices which are used to measure and check the accuracy of the various machining cuts on the parts. Jigs and fixtures are holding devices which position the parts in place on the machines while they are being cut to the desired size and shape.

Most jigs and fixtures in tool engineering consist of a number of moving or adjustable parts. Such devices frequently contain cams, gears, piping, or other intricate machine elements. Tools, gages, jigs, and fixtures are usually designed and built when large quantities of identical parts are to be made.

Their use has been found to save considerable shop time and expense in making parts. A typical tool design drawing (an assembly drawing of a drill jig) is shown in Fig. 1-4.

Fig. 1-4. A tool design drawing

The tool design department may, when necessary, suggest design changes affecting the product.

For example, changes may be suggested in cases where difficult or expensive machining operations could be simplified. Thus one department may serve as a check on another.

While the prototype is being designed, made, and tested, the department heads work together to estimate the probable costs in manufacturing and marketing the product. Sales and advertising literature is drawn up.

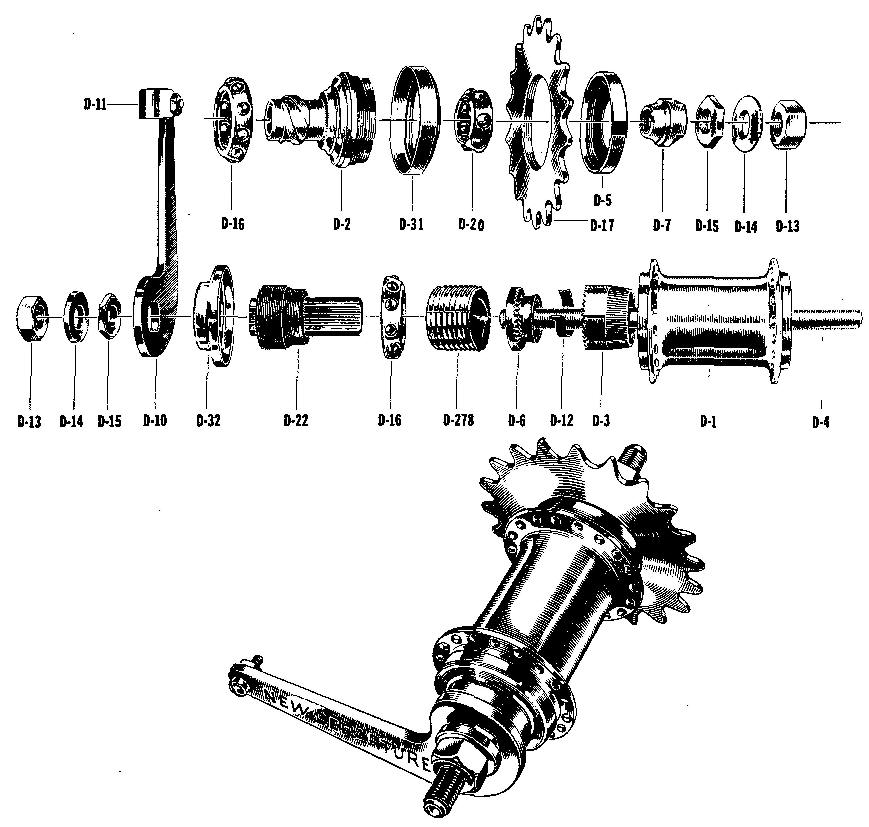

Drawings, diagrams, charts and graphs, and photographs are prepared for the various catalogs and brochures. Figure 1-5 shows a typical catalog illustration.

Fig. 1-5. A typical catalog illustration

The organization of a specific engineering department depends upon the needs of each industrial plant. Small companies often combine two or more jobs. Thus the product engineering and tool engineering departments might be headed by the same man, perhaps the chief engineer. The advertising and sales department might also be combined.

Within each department in some companies various personnel might be expected to perform a number of different duties. Such a draftsman must possess diversified skills. Advertising or catalog drawings require different standards than do engineering drawings.

The machine draftsman

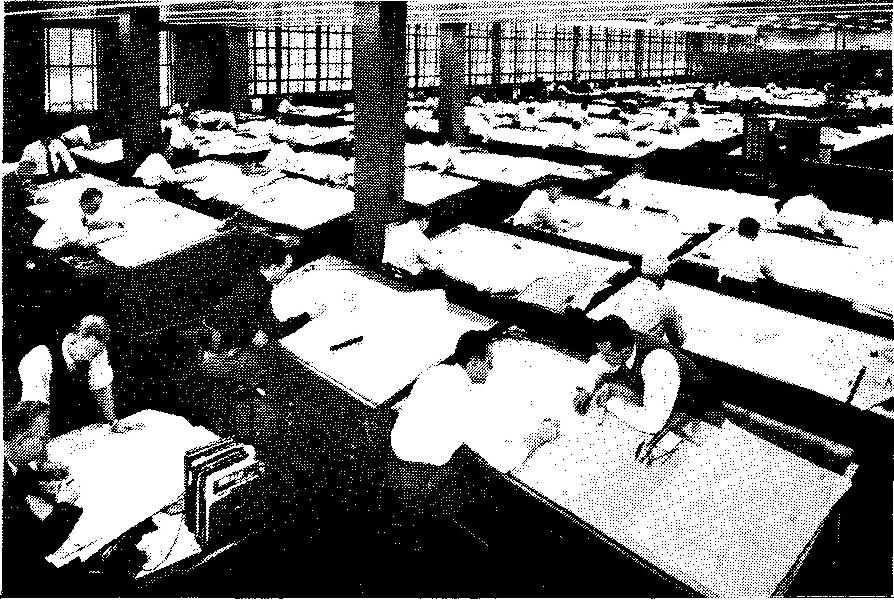

Under the supervision of engineers or designers, a machine draftsman works in one of the engineering departments of a company. A typical engineering department is illustrated in Fig. 1-6.

Fig. 1-6. A typical engineering department

Machine draftsmen are often called technicians, or engineering aids. They prepare drawings of one machine part or of groups of machine parts.

They often gather the required information from assembly drawings such as those shown in section Principles of assembly drawings. They are responsible for illustrating and specifying all information so that the parts may be made and assembled entirely from the drawings.

So complete are the drawings that no other written or verbal instructions should be necessary to supplement them. Machine draftsmen are expected to do neat, fast, and accurate work. It is estimated that industry requires at least four to six machine draftsmen for every engineer.

A machine draftsman's training

The beginning draftsman must have had a course or two in mechanical drawing and in technical mathematics at the high school level. Courses in machine drawing and shop training will usually increase a person's chances of employment.

In the past, men started as apprentice draftsmen and learned on the job. In modern times, however, practically all beginners should have some specialized training before employment.

Some companies organize their own special training courses for draftsmen. Many machine draftsmen also study part-time in technical schools or in colleges or take correspondence courses which usually improve their chances for advancement.

Some men eventually complete enough courses for a college degree in engineering. Machine draftsmen may also prepare drawings for the sales and advertising departments.

Here, the duties would generally consist of preparing the charts, diagrams, and other forms of graphic material useful in sales and advertising literature.

Work of this nature usually requires some knowledge of pictorial drawing. The ability to use mechanical lettering devices and inking instruments is also especially valuable in this work.

Tools and equipment

Students are taught in schools how to use a T square and drawing board. It should be understood that T squares and drawing boards are used in training because they are economical and require little storage space. Also, equipment of this kind is small enough to be portable.

Most industries use 4- by 6-foot drafting tables instead of individual drawing boards. Drawings are either stapled or taped directly onto the flat surface. Tables of this size permit the use of both small and large drawing sheets. Parallel straightedges or drafting machines are used, not T squares.

The parallel straightedge, Fig. 1-7, operates by means of pulleys and strings which are attached to the edges of the table.

Fig. 1-7. Drafting board with parallel straight edge

The straightedge may be freely moved over the top surface of the table, always remaining parallel to the top and bottom edges. Drafting triangles are held against the top of the straightedge much in the same way as triangles are used with the T square.

The drafting machine, Fig. 1-8, which is fastened to the table top, requires no triangles whatever.

Fig. 1-8. A drafting machine

It consists of two flat scales which are mounted at right angles to each other. A protractor device for tilting the scales can be used when drawing lines vertically, horizontally, or to any desired angle. In a short time, a person can become quite proficient with both the straightedge and the drafting machine.

Most companies provide draftsmen with pads of paper for sketching and calculations, and also with various grades of pencils and leads, erasers, staples, ink, tape, and all other similar items.

The draftsman is expected to provide his own drafting instruments, drafting triangles, curves, templates, and so on. Special or unusual equipment for drawing is usually purchased by the company.

Engineering departments have found that standards books, or drafting room manuals, save a great deal of time and expense.

These manuals usually consist of a set of loose-leaf pages which show examples of certain recommended drawing practices which the company requires for its drafting work.

Drawings and tables of sizes of many frequently used machine parts such as springs, taper and straight pins, fasteners (nuts, bolts, washers, cotter pins, keys, and so on), and other devices are also included in these manuals.

Whenever possible, commercially available parts are used in the design of a product. Use of standards books saves considerable research into commercial literature. Standard-size parts also reduce the number of parts a company might be required to keep in stock. Drafting room manuals are usually developed over a period of many years. New material is constantly added as needed.

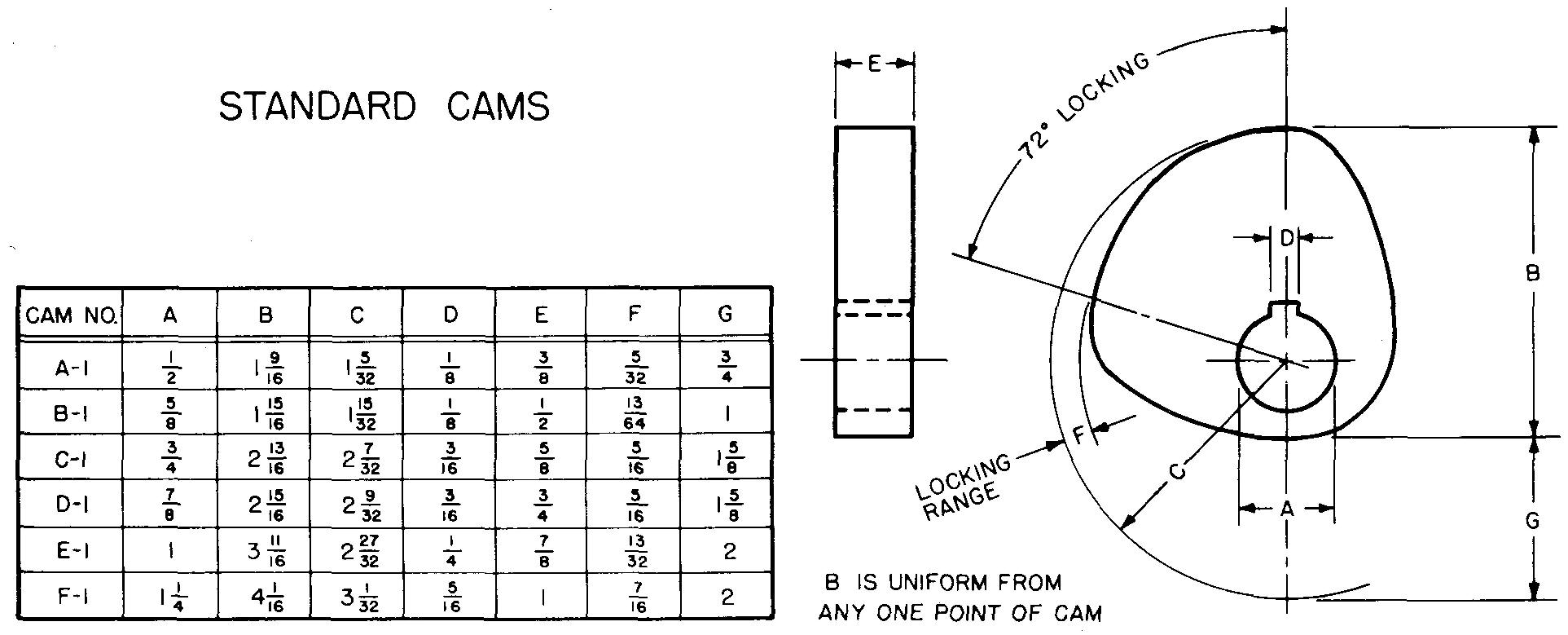

Figure 1-9 illustrates a typical page from a standards book.

Fig. 1-9. A page from a standards book

The student will use the Appendix of this book as the standards book for this course (see tables).

Practically all companies establish reference sections which consist of manufacturers' catalogs and bulletins, various handbooks, and technical books. These are available in drafting rooms for everyone to use as needed. Many machine draftsmen send for and collect various material of this kind.

The place of the machine draftsman within the engineering department

A machine draftsman may work in any one or all of the departments described above.

In production engineering he would prepare the final drawings of the product, often working from rough sketches or from design layouts prepared by the designers.

In tool engineering, a draftsman would prepare drawings of the special tools, gages, jigs, or fixtures which might be required for the product.

While some of the conventional drafting practices may vary slightly between the production and tool engineering departments, most machine draftsmen can, after a period of time, work effectively in each department.